Chain for hoists and lifting blocks

Having a good chain is important both for your safety and the lifespan of your hoist or lifting block. Is it time to replace the worn chain? We will help you.

Enerpac's cylinders are first class and deliver exceptional performance and reliability. With their robust construction, they excel in handling heavy lifting - with capacities up to 1000 tonnes.

Did you know that Enerpac cylinders are available in more than 100 different designs? Explore our diverse range of cylinder options to find the perfect fit for your industrial needs and desires. Improve your business with Enerpac!

Below you will also find mechanical jacks from Simplex. Qualitative products that can also lift heavy loads. With their robust construction and reliable performance, they can handle a variety of applications. Simplex also offers a wide range of jack types to suit your wants and needs. Take your lifting capacity to the next level with Simplex!

The RC series hydraulic cylinders are incredibly durable and versatile. These single-acting hydraulic cylinders are suitable for a wide range of applications, such as lifting, pressure or pressing. These hydraulic jacks include many advanced features for superior durability and productivity.

RR Series hydraulic cylinders are designed for double-acting use with hydraulic return, providing increased speed and control when retracting the shock for optimum performance.

The RCH series single acting hollow cylinders offer versatility in testing, maintenance and tension applications. The hollow cylindrical construction enables use for push, pull or lift applications.

The RRH series hollow cylinders are optimal for tension, test, tension and lifting applications. The hollow design enables the use of accessories for both pulling and pushing forces.

RACH series hole cylinders, also called center-hole cylinders, have a hollow cylindrical push rod with internal thread for attachment. Perfect for lighter and more portable uses such as tensioning, testing, pulling and lifting.

The RSM series low profile hydraulic cylinders provide high durability and safety in a compact format. Perfect for limited spaces, ideal for lifting and production.

The RCS series low profile hydraulic cylinders provide superior durability, performance, safety and quality in a compact format. Ideal for general lifting and production where space is limited.

As a leading player in mechanical transmissions and high-pressure hydraulics since the 1950s, we are Bengtssons Maskin proud to offer customers in the Nordics a wide range of cylinders for industrial machines. But what is a cylinder, and how does the choice of cylinder affect the machine's performance and areas of use? In this article we give you a deeper understanding of cylinders and how you can optimize your choice to achieve the best possible results.

A cylinder is a fundamental component in hydraulics and pneumatics that converts fluid pressure into mechanical motion. Cylinders are used in a variety of industrial machinery and equipment to perform motion in linear, rotary or combined form. They consist of a cylindrical body, a piston, and a piston rod that moves in and out of the body when pressure is applied or released.

When choosing a cylinder for your industrial machine, there are several factors to consider:

Cylinders are used in a variety of industrial machinery and applications, such as:

On Bengtssons Maskin we understand that choosing the right cylinder is critical to optimizing the performance and efficiency of your industrial machinery. That's why we offer our Trio Bearing System – an innovative cylinder design that improves both durability and side load resistance.

As your partner in industrial machinery and equipment since 1913, we are at Bengtssons Maskin committed to offering customer-focused solutions. We know that every application has unique requirements and challenges, and we are here to help you find the right cylinder for your specific needs.

Our assembly workshop in Arlöv is equipped to adapt our products physically to your specifications. We also offer advice, dimensioning and assembly on site at your company to ensure that you get an optimal and efficient solution.

On Bengtssons Maskin we value long-term relationships with our customers. By offering high quality products, technical expertise and personal service we help you become more competitive in your market and increase the profitability of your company.

Our watchwords – safety, efficiency, sustainability and profitability – permeate everything we do and ensure that we always strive to exceed your expectations.

Having a good chain is important both for your safety and the lifespan of your hoist or lifting block. Is it time to replace the worn chain? We will help you.

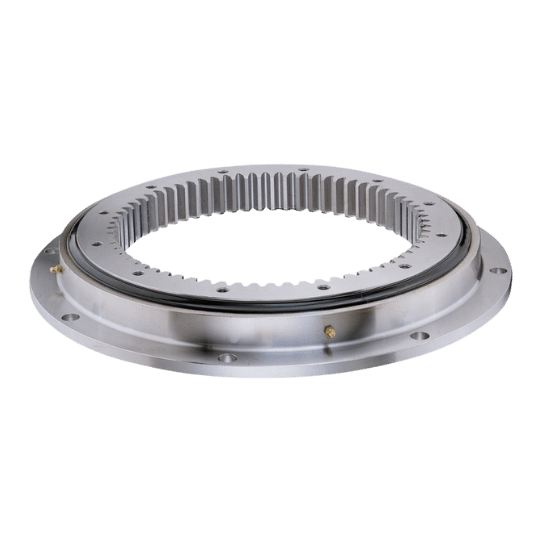

Slewing bearings for high axial, radial and tilting moments, reliable in demanding applications.

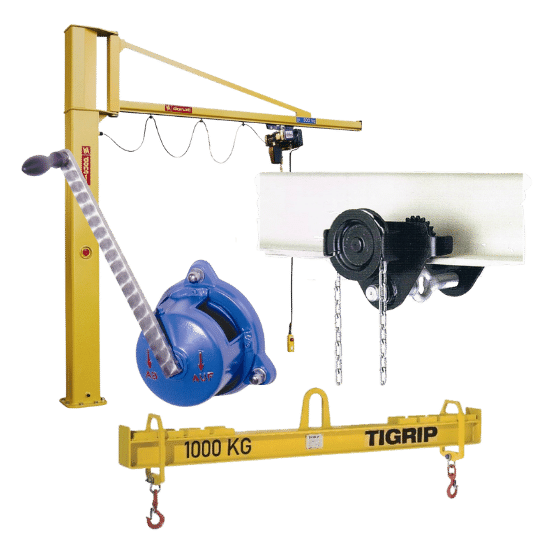

Here we have gathered other products within lifting. You will find various hand winches, slewing cranes, beam trailers and lifting devices.