Special shows

Are you looking for special screws? Then you have found the right place. We sell a very large range of special screws from NBK in Japan.

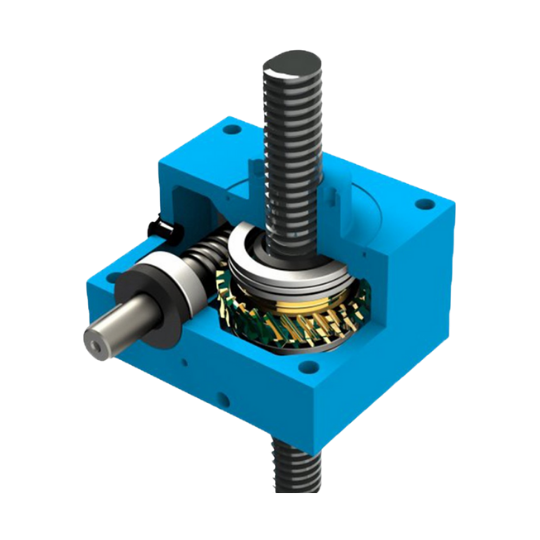

Worm gear jacks from UNIMEK SpA are easy to use, reliable and require a minimum of maintenance. This makes them a very useful machine element in many different contexts.

They can be used to lifting, pulling, balancing and positioning.

Even with very high demands on personal safety, the jack is a useful alternative because the worm screw in our jacks is 100% self-locking. They can be used without external braking or locking devices. The lifting force of our jacks is a maximum of 1000 kN.

Gearbox manufactured in aluminium, cast iron or steel depending on size.

Gearbox manufactured in aluminium, cast iron or steel depending on size

• Worm screw made of case-hardened steel 18NiCrMo5

• Worm wheel in bronze alloy

• Spindles of hardened carbon steel C40 with trapezoidal thread according to DIN 103

The pdf catalog is a shortened version. The complete catalog can be ordered from our sales staff

Our jacks can be adapted to most ball screws on the market.

Can be adapted for most ball screws on the market and can be delivered with or without the ball screw.

This series of jacks has a housing and worm wheel made of a composite material.

This means, among other things, that it can work without lubrication – an advantage in many built-in cases. Currently, aleph is available in three sizes, all with trapezoidal screws.

Are you looking for special screws? Then you have found the right place. We sell a very large range of special screws from NBK in Japan.

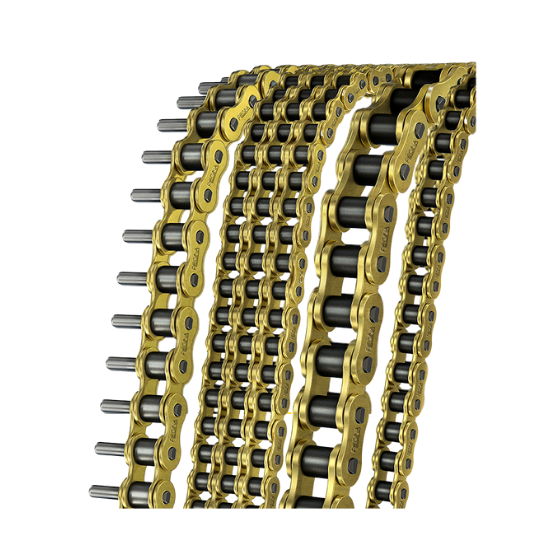

We have a very wide range of standard chains which are supplemented with a number of customer-unique chains. Read more about our products here.

Linear controls are a system where quality and a high level of technology are hallmarks. Rails and carriages are manufactured in aluminum for the lowest weight...

A jack is a mechanical tool used to generate a force necessary to perform a variety of tasks. Jacks are usually used to lift heavy objects or to tighten or loosen screws. They can also be used for other tasks that require a strong force, such as compressing materials or performing mechanical tasks.

There are many different types of jacks, including hand-held units such as screwdrivers and larger stationary units such as workbench jacks. Hand-held jacks are often manual and operated by a lever that the user pulls to transfer power to the tool. Stationary jacks can be manual or powered by electricity.

When using a jack, power is transmitted to the tool via a hand-operated lever or electric motor. A lever or handle that the user turns activates the mechanism that generates the force. The power generated is controlled and can be adjusted depending on what needs to be done.

It is important to use a jack safely and effectively. This means choosing the right jack for the job and following guidelines for safe use. It is also important to monitor the power level to avoid damage or injury to the tool or the thing to be fixed.

Unlike other tools for power production such as manual tools such as hammers and wrenches, give jacks a more controlled and adaptable force. This makes them widely used for a wide range of uses, from simple home repairs to professional workshop work.

Jacks are a versatile tool used in a variety of contexts. They are common for both domestic and industrial uses. Here are some of the most common uses for jacks:

Automotive and transportation industry: Jacks are often used in the automotive and transportation industry to assemble and disassemble parts in automobile engines, tires, and other equipment.

Construction Industry: Jacks are essential tools for many construction tasks, such as assembling and disassembling building materials, tightening and loosening screws, and lifting heavy objects.

Workshop work: Jacks are essential tools in workshop environments for performing precision work such as tightening or loosening screws, as well as loosening attached objects with high force.

Electronics Repair: Jacks are often used to open and repair electronic devices such as computers, phones, and TVs.

Peripherals for industrial equipment: Jacks are used to assemble and disassemble peripherals for industrial equipment, such as pumps, compressors and coupling fittings.

A jack is a mechanical device that transfers power from a hand-held operable part to a voltage divider. It is a simple but powerful machine that uses mechanical distribution to increase power.

Another common type of puller is mechanical pullers. These tools are used to remove large or difficult components that are stuck. They use a combination of force and mechanical principles to remove the components safely and efficiently.

There are also hydraulic pullers that use hydraulics to apply force to remove components. These are especially useful when working with heavy or large objects that may be difficult to handle with traditional tools.

When choosing a jack for a particular task, you should consider the following factors:

Loading: Determine the weight of the load to be lifted or bolted down.

Arm length: Determine the arm length you need to reach and handle the load safely.

Power requirement: Determine how much power is required to handle the load. This information is usually available from the manufacturer or can be calculated using a load calculator.

Location: Decide where the jack will be used and if there are any special conditions, such as limited space or surrounding obstacles, that you need to take into account.

Frequency of use: Decide how often the jack will be used and if it needs to be robust and durable for heavy duty tasks.

Available equipment: Consider what other equipment you have available, such as safety equipment, that may be required to operate the jack safely.

The following steps should be followed to use a jack safely and effectively:

Read and understand the user manual before using the jack. Follow all safety instructions and instructions for use.

Use the right safety equipment: Use safety equipment such as protective gloves, protective clothing, safety shoes and safety glasses.

Check the equipment: Check the equipment, including the jack, before each use to make sure everything is in good condition.

Set the right arm length: Set the arm length to suit the area where you will be working and ensure a comfortable and safe working position.

Use fasteners: Use fasteners such as clamps or hooks to ensure that the load is properly secured and cannot fall or move.

Use proper technique: Use proper technique to handle the load, including avoiding overloading and keeping the jack even to prevent uneven loading and injury.

Use the jack for the right task: Use the jack for the task it is intended for and not for any other purpose.

Store the jack properly: Store the jack in a dry and safe place, and avoid exposing it to the elements.

By following these steps, you can use the jack safely and effectively and avoid injury to yourself or others.

Efficiency: A jack is a very effective tool for handling loads and performing powerful tasks. It can produce large amounts of force with very little effort, making it suitable for a variety of tasks.

Versatility: Jacks come in many different sizes and models, making them versatile and suitable for a variety of tasks. You can choose a jack suitable for your specific task and work area.

Concentration of power: A jack increases the force on the load by concentrating the force on a small area, making it easier to handle large loads.

Safety: Jacks are safe to use when used properly and with proper safety equipment. They minimize the risk of injury and allow a user to perform heavy duty tasks with lower risk.

Conservation of forces: Jacks can help conserve the user's strength by making it easier to handle heavy loads, which can be important for users with limited strength.

Cost effectiveness: Jacks are often more cost effective than other power generation tools, especially for larger tasks that would otherwise require the use of multiple people or other power tools.

By considering these benefits, you can determine whether a jack is suitable for your specific task and choose the tool that best meets your needs.

Quality: Bengtssons-maskin.se are known for offering high-quality jacks from leading manufacturers. You can be sure to get a jack that is robust and reliable and will perform well for your specific task.

Range: Bengtssons-maskin.se has a wide range of jacks in different sizes and models, which gives you the opportunity to choose a jack that is suitable for your specific task.

Customer service: Bengtssons-maskin.se are known for offering excellent customer serviceservice, including advice on which jack is best for your specific task. You can get help and support throughout the entire process from selection to purchase.

Price: Bengtssons-maskin.se offers competitive prices on its jacks, which makes it easier to get a quality jack at a reasonable cost.

Shipment: Bengtssons-maskin.se offers fast and reliable deliveries, so you can get your new jack quickly and easily.

Warranties and aftermarket support: Bengtssons-maskin.se often offers warranties and aftermarket support for its jacks, so you can be sure you get the support you need after the purchase.

By considering these factors, you can decide if Bengtssons-maskin.se is the right place for you to buy your next jack.