Special shows

Are you looking for special screws? Then you have found the right place. We sell a very large range of special screws from NBK in Japan.

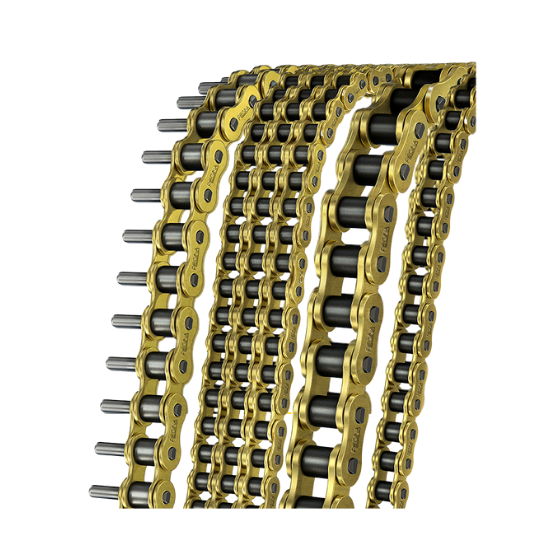

A very wide range of standard chains that are supplemented with a number of customer-unique chains.

Material selection and function can be varied endlessly and gives us great opportunities to find effective solutions for most applications.

Here we only show a small selection of all the special chains we sell, and for further information about special chains, please contact our sellers.

Regina Industria is one of Europe's most complete manufacturers of roller chains. With three factories in Italy, one in Argentina and one in the USA, they have a full range of standard roller chains in both DIN and ANSI standards.

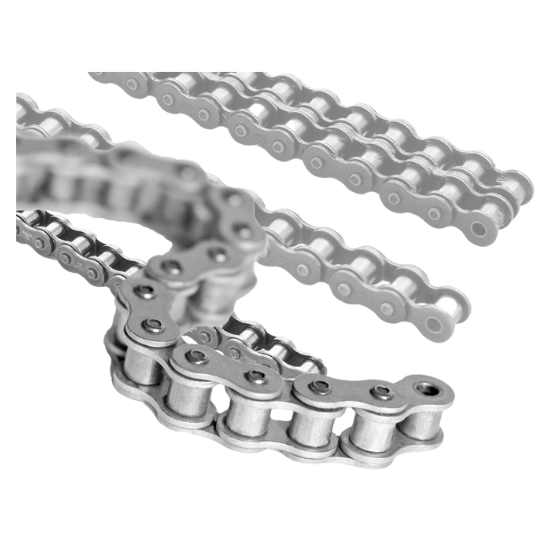

A very large proportion of the production is stainless roller chains in various types of material. Also these both in DIN and ANSI standard

These maintenance-free roller chains with plastic inner links and stainless steel outer links are a grease-free series of roller chains suitable for various transport purposes in e.g. packaging machines as well as for lighter drive applications.

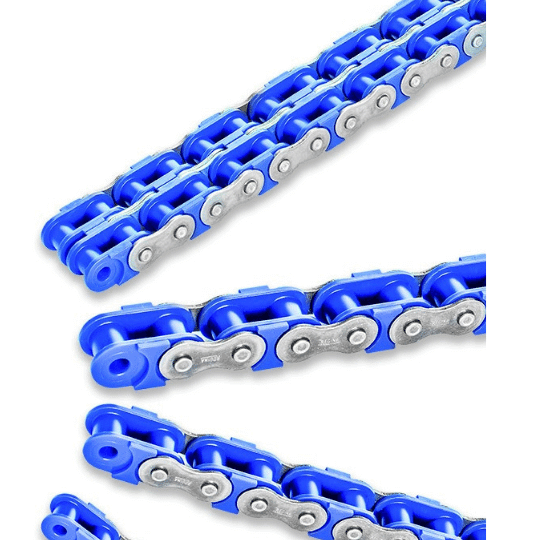

All dimensions can be provided with various types of standard or specially manufactured according to customer drawings.

Material selection and function can be varied endlessly and gives us great opportunities to find effective solutions for most applications. Here we only show a small selection of all the special chains we sell, and for further information about special chains, please contact our sellers.

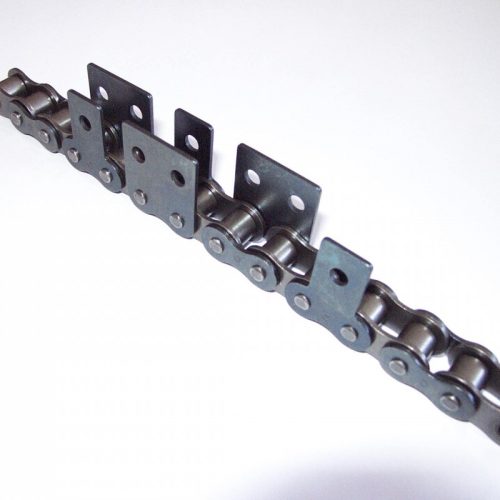

A large part of the special chains we deliver are equipped with different types of carriers.

Regina provides a large number in standard design but also has many variants that are customized.

This chain consists of a standard roller chain with extended bolts and a tapered knob.

The application is a packaging machine and we assemble the conical knob with a special tool. The button is supplied by a subcontractor.

This chain consists of a standard roller chain with extended bolts and a tapered knob.

The application is a packaging machine and we assemble the conical knob with a special tool. The button is supplied by a subcontractor.

Regina has developed a series of grab chains for vacuum formers of various makes.

We can supply chains that fit the most common machines on the Swedish market.

The picture shows a folding "pusher" for the transport of corrugated boxes in a packaging machine.

The basic chain is Regina's maintenance-free ENDURO and the carrier is made of stainless steel.

When the chain passes over the sprockets, the driver folds down against the chain.

Are you looking for special screws? Then you have found the right place. We sell a very large range of special screws from NBK in Japan.

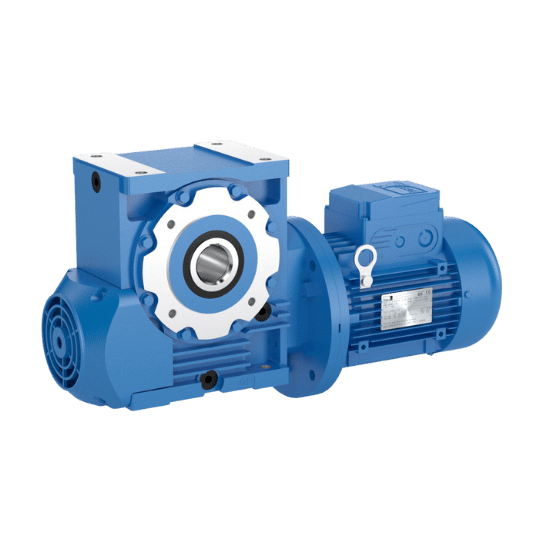

With Rossi's product range, we have the world's widest range of gears. Here you will find gears that are included under precision.

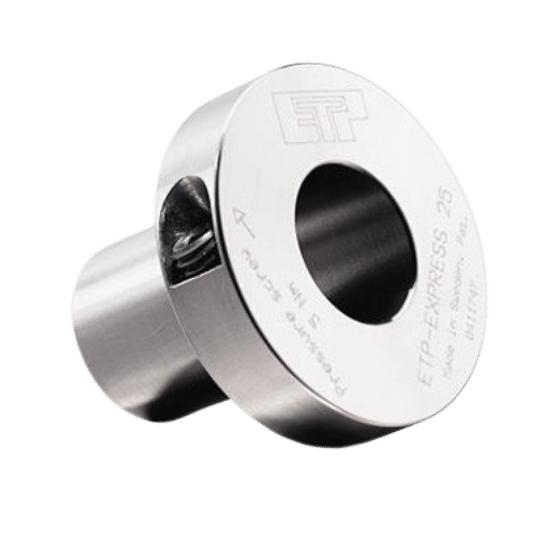

Due to the hydraulic working method, the ETP principle provides a number of important advantages for the customer: compact design, quick assembly, easy to position, good rotation, does not damage the contact surfaces and is easy to dismantle.