Gearboxes

Looking for gears? We have a wide range of gears. Here you will find everything from geared motors with helical and bevel helical gears to planetary gears.

Efficiency and protection with the right elastic connection

Resilient couplings are invaluable components to ensure uninterrupted operation. Their unique characteristics allows them to compensate for less displacements, while effectively dampening harmful shocks and vibrations.

In this way, machines and equipment are protected from stressful loads that can cause costly downtime and repairs. By investing in en elastic coupling you maximize productivity and profit in the business.

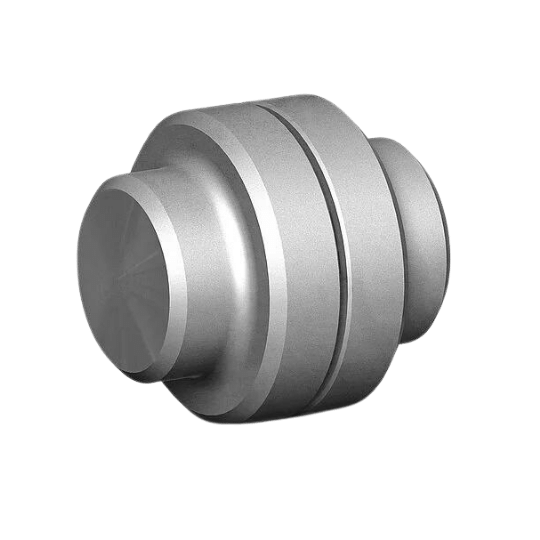

FLEXOMAX G is a torsionally flexible coupling with compressible flexible elements. It compensates for axial, radial and angular movement between axles, absorbs rotational wear and torsional vibrations from engines or machinery. The rubber part can withstand dirt, water, oil and tough conditions.

Available in 18 sizes with capacity up to 97,20 kNm and shaft diameter up to 250 mm.

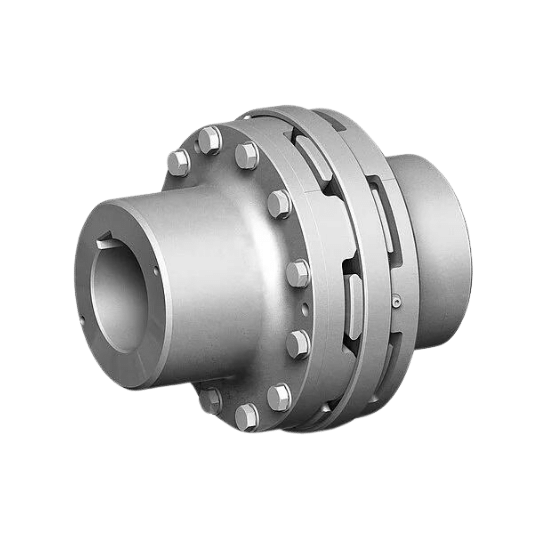

The FLEXOMAX GBN coupling is flexible and torsionally elastic, allowing it to handle misalignment and absorb shock and vibration. Its polyurethane elastic elements are resistant to chemical aggression.

Easy to install and requiring minimal maintenance, it offers high torque transmission capacity in a compact design, making it suitable for low-speed shaft applications.

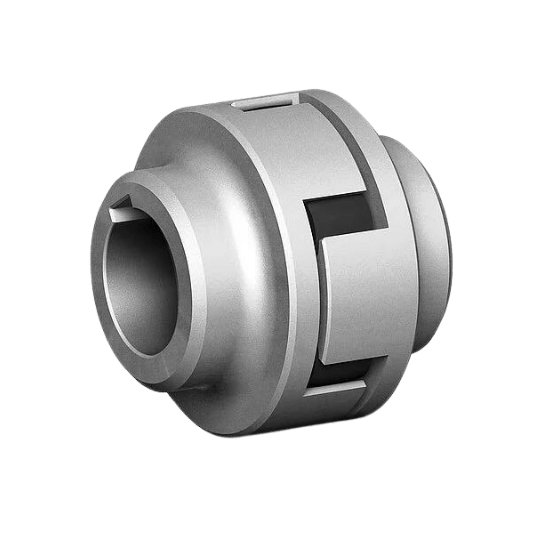

FLEXOMAX GSN is a torsionally flexible coupling with compressible flexible elements suitable for electric motors on high speed bowls. It compensates axial, angular and radial displacements between axles and absorbs shocks and vibrations. The coupling's flexible properties can absorb torque and vibration on both the drive side and the PTO side. The flexible elements are made of polyurethane and are water, oil and dirt resistant.

Elastic couplings fulfill an important function in a variety of industries and applications. Thanks to their ability to compensate for displacements in both axial and radial directions, as well as dampening harmful vibrations, these elastic couplings can minimize damage not only to the coupling itself, but to the entire machine.

A common use is high-torque applications that place demands on both machine and coupling. Here, an elastic coupling shines with its dynamic construction.

Elastic couplings are also indispensable in environments where the shafts are subjected to axial and radial displacement. Their flexibility allows for mobility while the vibration damping ensures trouble-free operation.

Finally, elastic couplings are widely used in harsh environments with the presence of dirt, water, oil or aggressive chemicals. Their robust construction resists stress and provides a long service life even under adverse conditions.

Regardless of industry or application, a properly selected elastic coupling is a critical component in minimizing downtime, repair costs and production losses.

The FLEXOMAX series of elastic couplings is the result of the effort to offer the best products on the market. Through years of experience and continuous product development has VOLCANO, creators of FLEXOMAX, honed every detail to maximize quality, reliability and longevity.

The "core" of the couplings is carefully designed and manufactured in durable materials such as polyurethane. Their robust and compact design makes them easy to assemble and maintain, as well as smart construction that minimizes the risk of breakdowns and production stoppages.

Whether you choose the FLEXOMAX GSN for high-speed applications, the versatile FLEXOMAX G or the chemical-resistant FLEXOMAX GBN, you can count on outstanding performance and reliability. Quality is our top priority to ensure your productivity.

On Bengtssons Maskin we have long experience in delivering high-quality elastic couplings adapted to the toughest requirements that your industry faces.

Regardless of whether you need a coupling for high torques, demanding environments or special shaft alignments, we have the solution in our FLEXOMAX series.

Contact already today for a review of your needs. We guide you to the optimal elastic coupling for maximum reliability, minimal downtime and increased profitability. Our experts are ready to answer all your questions.

Looking for gears? We have a wide range of gears. Here you will find everything from geared motors with helical and bevel helical gears to planetary gears.

Looking for chain or lifting eyes? Then you have found the right place! We have lifting eyes and chain in different classes: Class 10 VIP, Mini chain Class 10 and Class 12 ICE.

Having a good chain is important both for your safety and the lifespan of your hoist or lifting block. Is it time to replace the worn chain? We will help you.