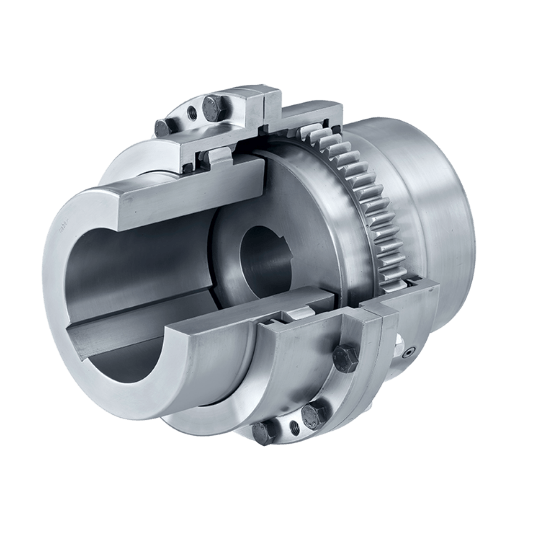

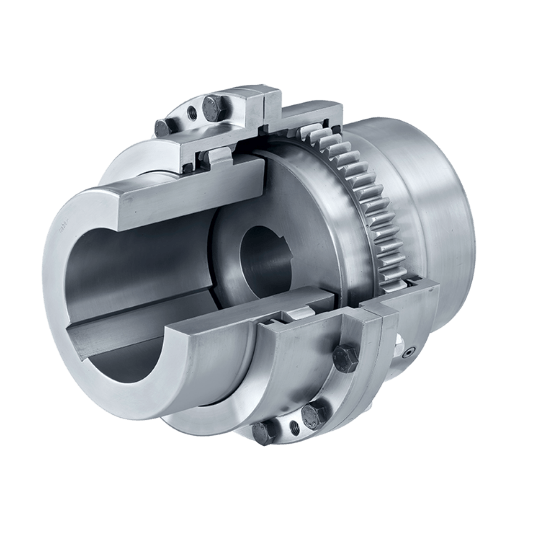

Gear couplings

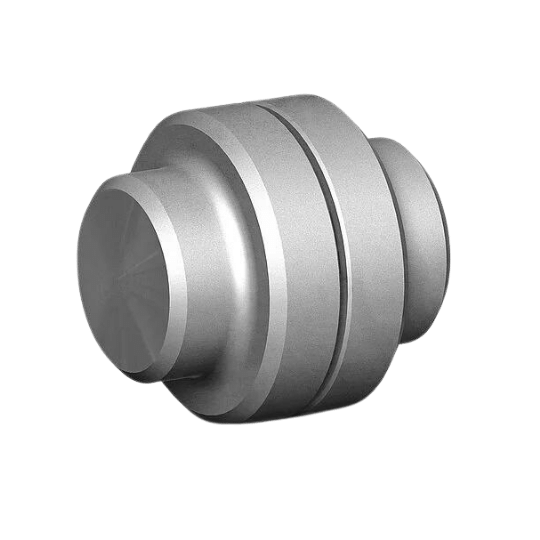

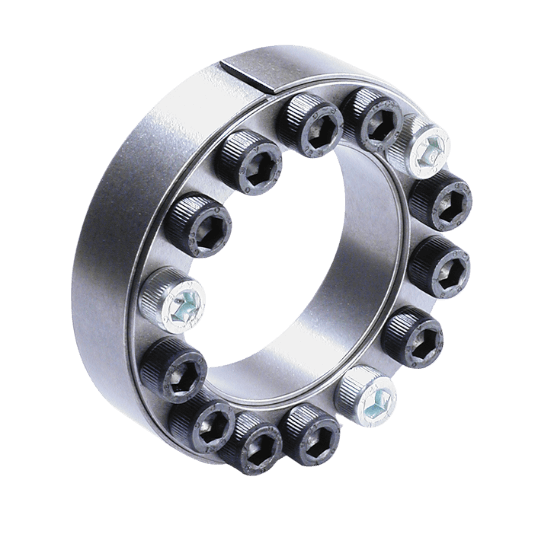

All mechanical friction joints are based on the principle of cones sliding against each other. The sliding and thus the radial expansion, brought about…

With Rossi's product program, we have the world's widest range of gears.

All manufacturing takes place at two factories in Italy. All components are manufactured locally. The gears from Rossi can be combined with other products from our range, such as slewing rings, cardan shafts and clamping joints.

Do you want to read more about Rossi? Click here.

Below you will find all products with respective catalogues.

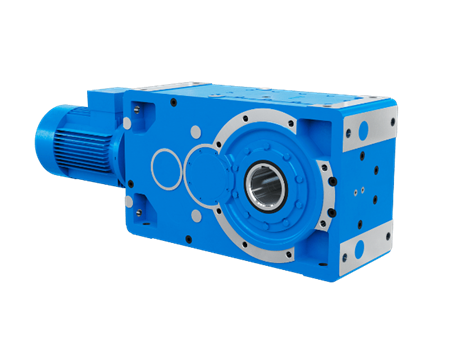

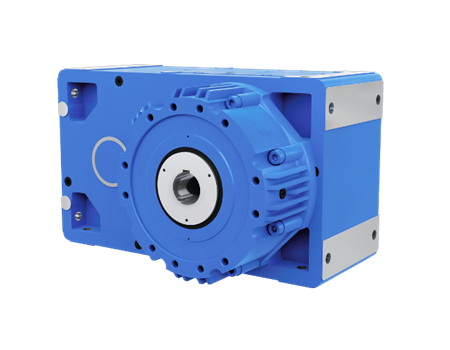

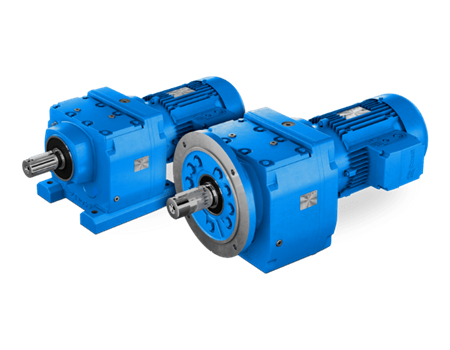

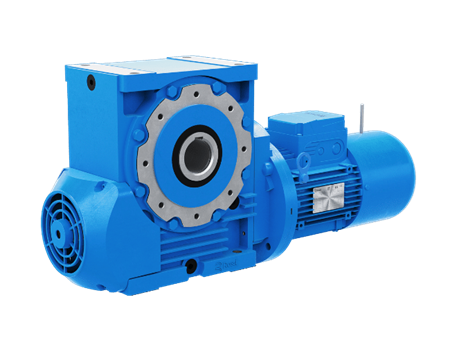

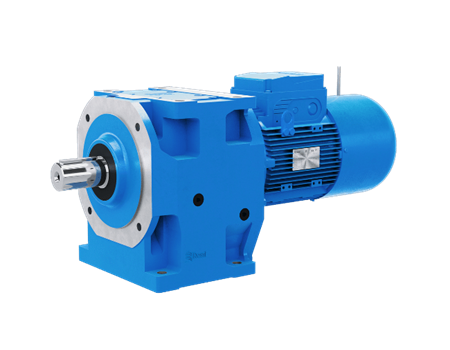

This range of gear reducers and geared motors combines and enhances the traditional characteristics of helical and helical helical gear reducers (strength, precision and reliability) with advantages derived from modern design, manufacturing and operating criteria.

Standard and extended models of helical gear reducers and gear motors with extruder support. Based on the standard series with parallel and right-angle axes, redesigned extruder support flange with wide support surfaces.

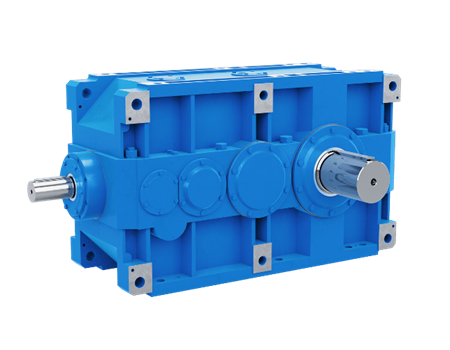

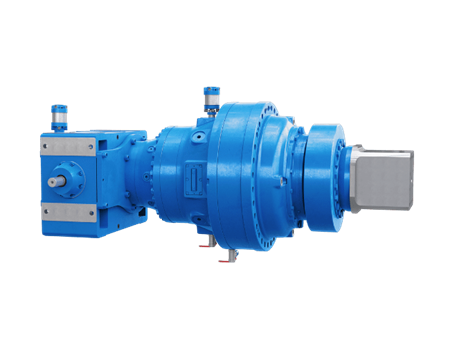

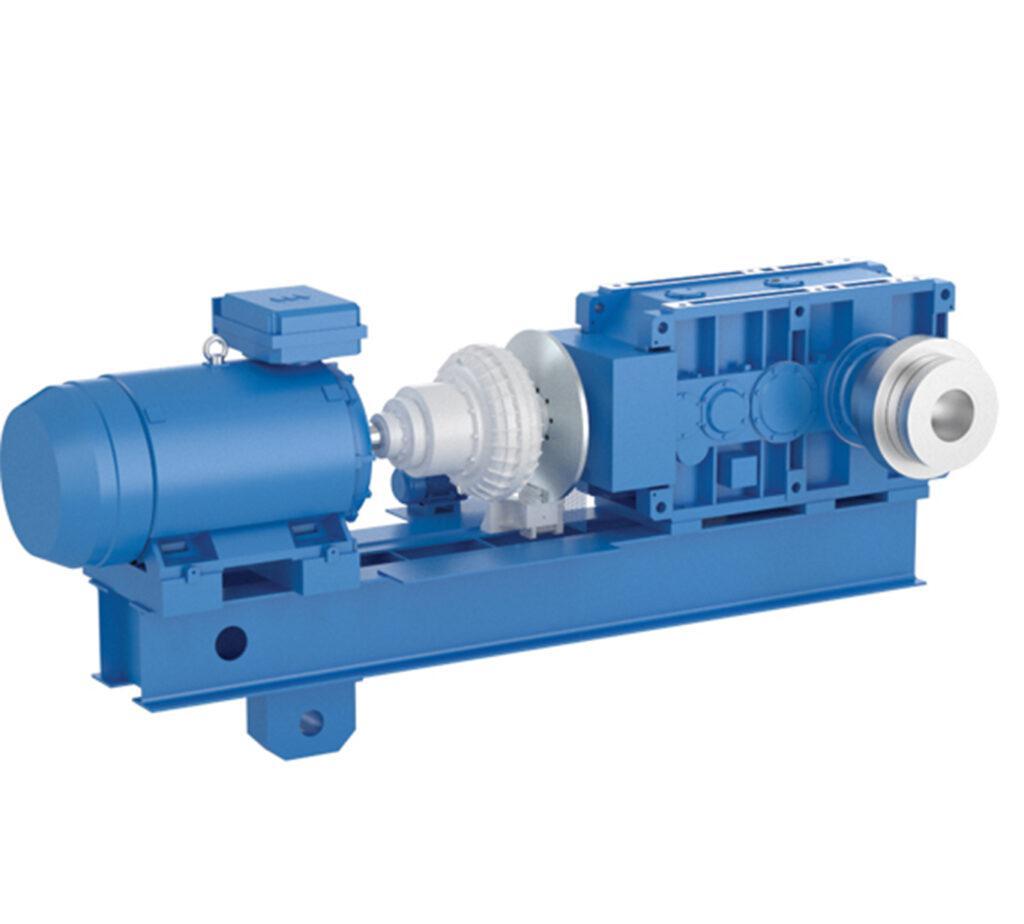

Large scale gear reducers produced specifically to ensure the highest reliability under the most demanding operating conditions.

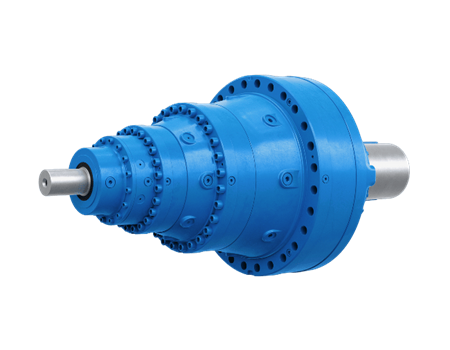

Planetary gearboxes are designed using the most advanced technologies and utilize the experience gained in all the most demanding applications. A complete range of gearboxes, suitable for every type of product in the industrial sector.

Modular gearboxes for customized solutions where maximum torque, maximum carrying capacity, high transmission ratio, high efficiency and long service life are required.

Grown from the experience of planetary gearboxes, oscillation drive systems offer the highest output torque within the range of 9 kNm to 400 kNm as well as high maximum load capacity. They can benefit from the widest range of functions from the catalog of planetary gearboxes.

iFit is the new gear in the Rossi series of high-performance geared motors that can be easily integrated with any industrial machine, without re-engineering costs.

Compact design solution, fully interchangeable with superior quality to suit any industrial application that improves business productivity.

Universal mount with feet integrated with the body. High, reliable and tested performance. Compactness, standardized dimensions and compliance with standards.

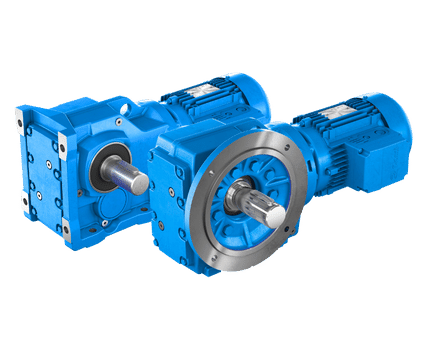

Gear boxes and gear motors with universal fixing housing and reinforced output support. Possibility to mount large motors according to IEC standard and square flanges to match the dimensions of servo motors.

Drive unit on the swing base RE series

Careful design and choice of equipment. Unique reference for commercial and technical matters. Entire unit certified upright.

Angular gears L series. Right-angled units with more options. Compact design. Rigid and durable cast iron housing. Multiple output options, solid or hollow shafts. Low gears available. Capacity for multiple devices synchronized.

Shaft mounted gear reducers are mainly used to drive conveyor belts but also for other machines such as rotating screens, screw conveyors, mixers, crushers and elevators where shaft mounting is possible and belt drive is needed between motor and gear reducer.

Gearboxes are an important part of any industrial machinery, as they help convert power from an engine into the movement of the machine. A gearbox makes it possible to obtain higher speed and lower torque or lower speed and higher torque, depending on the application of the machine. In this article, we will take a closer look at gearboxes made for industrial machinery, including what to consider when choosing the right gearbox for different machines and industries.

An industrial machinery gearbox is a device used to transmit power from an engine to a machine. It makes it possible to obtain higher speed and lower torque or lower speed and higher torque, depending on the application of the machine. Gearboxes are available in different sizes and designs and are manufactured to cope with different loads.

There are several factors that influence the selection of gears for a machine, such as

There are different types of gearboxes for industrial machines, and the choice of gearbox depends on the application and requirements of the machine. Here are some common types of gearboxes:

En planetary gear consists of a central fan and several surrounding planetary gears that rotate around the fan. These are often used in applications that require high speed and high torque.

Cylindrical gearboxes consists of two cylindrical gears that rotate around each other. These are often used in applications that require high efficiency.

Bevel gears consist of two bevel gears that rotate around each other. These are often used in applications that require high load capacity.

Variable ratio transmissions allow the user to adjust the ratio to optimize the machine's performance for different applications.

Angular gearboxes are often used in applications that require an angle change between motor and machine.

Gearboxes are used in a variety of industrial applications. Here are some common uses:

Gears are often used in manufacturing processes to drive machines such as lathes and milling machines.

Transmissions are used in the transportation industry to drive vehicles such as trucks, buses, and trains.

Gearboxes are used in the power generation industry to drive generators and turbines.

Gearboxes are used in the construction industry to drive machines such as cranes and drilling machines.

Gearboxes are used in the agricultural industry to drive machines such as combine harvesters and tractors.

Gearboxes are an important part of any industrial machine, and choosing the right gearbox is critical to the machine's performance and longevity. By taking into account factors such as efficiency, durability, load capacity, noise level, maintenance and cost, you can choose a gearbox that suits the machine's requirements and area of use. There are different types of gearboxes for industrial machinery, including planetary gears, cylindrical gearboxes, bevel gearboxes, variable ratio gearboxes and bevel gearboxes. Common applications for gearboxes include manufacturing, transportation, power generation, construction and agriculture.

All mechanical friction joints are based on the principle of cones sliding against each other. The sliding and thus the radial expansion, brought about…

The FLEXOMAX series consists of three different coupling variants: GSN, G and GBN.

We stock a large number of different types of clamping elements for different purposes and for a large number of shaft diameters.