Telfrar

Are you looking for lifters? We have plenty of telephone frames in standard design and we often make adaptations. Read more about our products...

Hydraulic pumps are indispensable in many industries, including manufacturing, construction, agriculture and automotive. They enable efficient transmission of power and control of movement, making it possible to lift heavy objects, perform precision movements and perform a variety of work tasks. The choice of hydraulic pump depends on the application's specific needs and requirements for pressure, flow etch efficiency.

Read more about our pumps below.

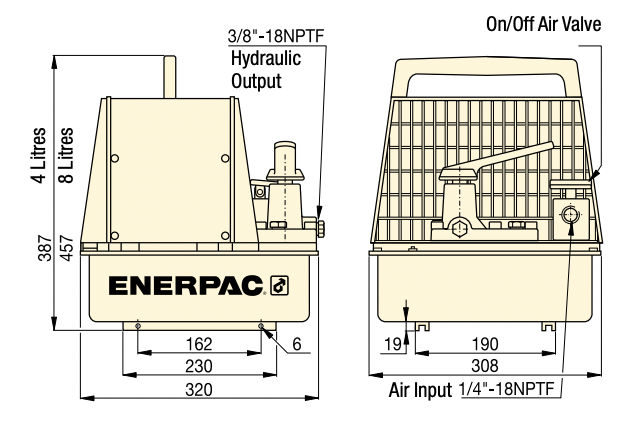

Dual air motor configuration provides high flow performance up to 14 bar for fast cylinder advance. 4 and 8 liter containers fit various cylinders with built-in housing for protection and portability.

| Used With Cylinder | usable Oil Chap. | Model Number with Shroud | Pressure Rating | Output Flow Rate (L / min) | Output Flow Rate (L / min) | Valve Function Valve | Valve Type | Air Pressure Range * | Air Consumption | Sound Level | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| (litres) | (Bar) | 1th stage | 2nd stage | (Bar) | (L / min) | (DB) | (kg) | ||||

| Single Acting | 2,6 | PAM1021 | 700 | 10,65 | 0,15 | Advance / Hold / Retract | 3/2 | 4,1 – 8,3 | 510 | 87 | 22,7 |

| Single Acting | 7,6 | PAM1022 | 700 | 10,65 | 0,15 | Advance / Hold / Retract | 3/2 | 4,1 – 8,3 | 510 | 87 | 27,2 |

| Double acting | 2,6 | PAM1041 | 700 | 10,65 | 0,15 | Advance / Hold / Retract | 4/3 | 4,1 – 8,3 | 510 | 87 | 22,7 |

| 7,6 | PAM1042 | 700 | 10,65 | 0,15 | Advance / Hold / Retract | 4/3 | 4,1 – 8,3 | 510 | 87 | 27,2 |

The PA series has advanced features such as adjustable relief valve, return port, internal relief valve, quiet operation (76 dBA), wide air pressure range, high efficiency air motor, lightweight container and remote control. Ideal for various demanding applications.

Here you will find technical information about the PA series. Read more in the catalogue.

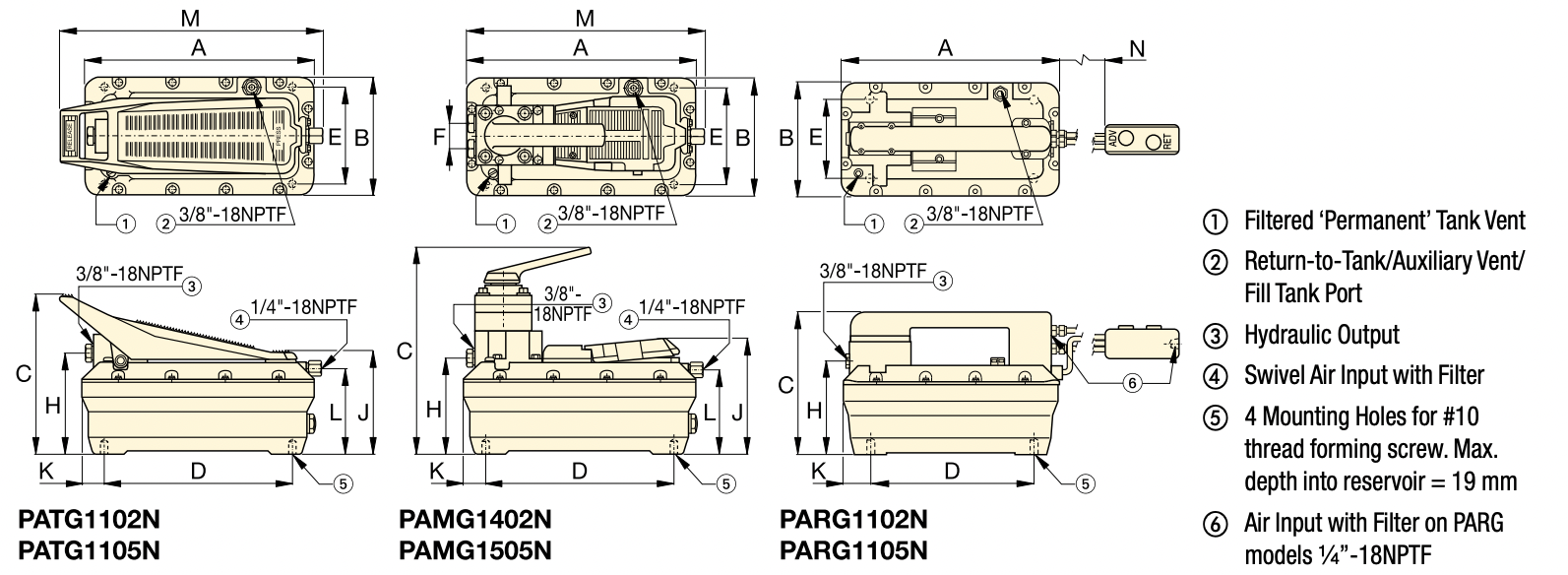

PATG models uses a foot or hand operated pedal to control air and valve functions.

PAMG models uses pedal with a locking function to control air, and a 4-way manual valve to control hydraulics.

PARG models uses air pendulum for remote control.

| Used with cylinder | Usable Oil Capacity (cm3) | Model Number |

|---|---|---|

| Single Acting | 2081 | PATG1102N |

| Single Acting | 3770 | PATG1105N |

| Single Acting | 2081 | PARG1102N |

| Single Acting | 3770 | PARG1105N |

| Double Acting | 2081 | PAMG1402N |

| Double Acting | 3770 | PAMG1405N |

| Valve surgery | (Mm) | Model number | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | H | J | K | L | M | N | (kg) | ||

| Treadle 3/3 | 313 396 | 165 201 | 211 209 | 230 230 | 102 102 | - - | 129 131 | 146 146 | 42 86 | 113 112 | 347 437 | - - | 8,2 9,9 | PATG1102N PATG1105N |

| Air Pendant 3/3 | 313 | 165 | 200 | 230 | 102 | - | 129 | - | 42 | - | - | 4500 | 10,0 | PARG1102N |

| 396 | 201 | 209 | 230 | 102 | - | 131 | - | 86 | - | - | 4500 | 11,7 | PARG1105N | |

| Manual 4/3 | 313 | 165 | 267 | 230 | 102 | 36 | 130 | 152 | 42 | 113 | 315 | - | 11,0 | PAMG1402N |

| 396 | 201 | 267 | 230 | 102 | 36 | 132 | 152 | 86 | 112 | 405 | - | 12,7 | PAMG1405N | |

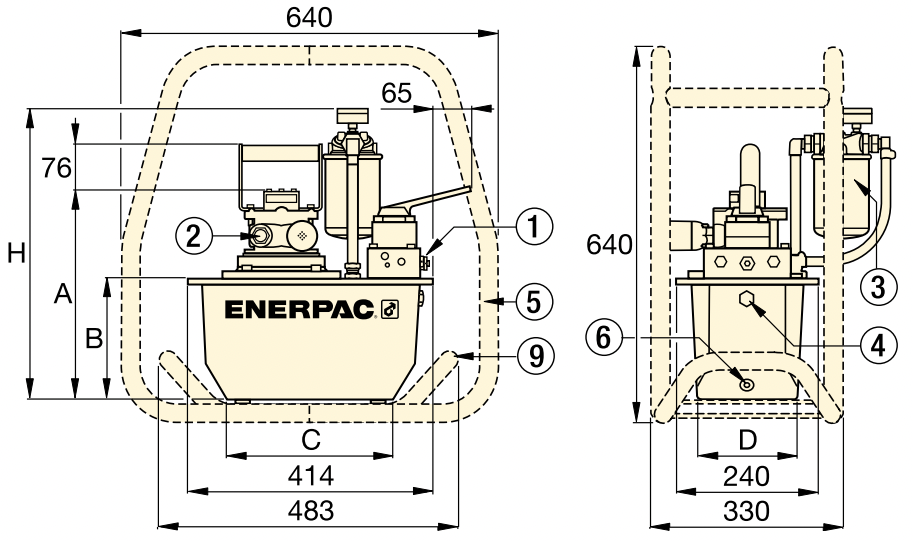

The ZA4 series is ATEX 95 certified for potentially explosive areas and features a high efficiency pump design, two speed operation, user adjustable relief valve, and optional heat exchanger for antifreeze and oil cooling. Oil level glasses and indicators are available for different reservoir sizes.

ZA4 series catalog (PDF)

Below you will find some tables belonging to the ZA4 series, read more about the product in the catalog.

| Used With Cylinder | Reservoir Size | Manual Valve 1) Model Number | Valve Function | Model Number | Output Flow Rate 2) | Relief Valve Adjustment Range | Maximum Air Consumption 3) |

|||

|---|---|---|---|---|---|---|---|---|---|---|

| (litres) | At 7 bars | At 50 bars | At 350 bars | At 700 bars | (Bar) | (L / min) | ||||

| - | 4,6 | - | - | ZA4004NX | 14,0 | 11,0 | 1,8 | 1,3 | - | 2840 |

| Single acting | 4,6 | VM32 | Advance / Retract | ZA4204MX | 14,0 | 11,0 | 1,8 | 1,3 | 70 – 700 | 2840 |

| Single acting | 6,8 | VM33 | Advance / Hold / Retract | ZA4308MX | 14,0 | 11,0 | 1,8 | 1,3 | 70 – 700 | 2840 |

| Single acting | 9,8 | VM33L | Advance / Hold / Retract | ZA4610MX | 14,0 | 11,0 | 1,8 | 1,3 | 70 – 700 | 2840 |

| Double acting | 4,6 | VM43 | Advance / Hold / Retract | ZA4404MX | 14,0 | 11,0 | 1,8 | 1,3 | 70 – 700 | 2840 |

| Double acting | 6,8 | VM43 | Advance / Hold / Retract | ZA4408MX | 14,0 | 11,0 | 1,8 | 1,3 | 70 – 700 | 2840 |

| Double acting | 9,8 | VM43L | Advance / Hold / Retract | ZA4810MX | 14,0 | 11,0 | 1,8 | 1,3 | 70 – 700 | 2840 |

| Double acting | 19,8 | VM43 | Advance / Hold / Retract | ZA4420MX | 14,0 | 11,0 | 1,8 | 1,3 | 70 – 700 | 2840 |

| Double acting | 39 | VM43 | Advance / Hold / Retract | ZA4440MX | 14,0 | 11,0 | 1,8 | 1,3 | 70 – 700 | 2840 |

| Sound Level | Motor size | (Mm) | Model Number | ||||||

|---|---|---|---|---|---|---|---|---|---|

| (DB) | (KW) | A | B | C | D | E | H | (kg) | |

| 80 – 95 | 3,0 | 295 | 142 | 279 | 152 | - | 429 | 27 | ZA4004NX |

| 80 – 95 | 3,0 | 295 | 142 | 279 | 152 | - | 429 | 30 | ZA4204MX |

| 80 – 95 | 3,0 | 356 | 203 | 279 | 205 | - | 490 | 34 | ZA4308MX |

| 80 – 95 | 3,0 | 330 | 180 | 414 | 421 | 500 | 467 | 51 | ZA4610MX |

| 80 – 95 | 3,0 | 295 | 142 | 279 | 152 | - | 429 | 31 | ZA4404MX |

| 80 – 95 | 3,0 | 356 | 203 | 279 | 205 | - | 490 | 35 | ZA4408MX |

| 80 – 95 | 3,0 | 305 | 155 | 419 | 305 | 384 | 442 | 40 | ZA4810MX |

| 80 – 95 | 3,0 | 330 | 180 | 414 | 421 | 500 | 467 | 52 | ZA4420MX |

| 80 – 95 | 3,0 | 419 | 269 | 399 | 505 | 584 | 556 | 75 | ZA4440MX |

The Enerpac XA series of pneumatic hydraulic foot pumps are the ideal choice for hands-free use. All models offer two control pedals to increase and release pressure to the tool. A pedal lock function can be used in the retract position. The XA foot pump provides fine metering controls to apply mandatory stroke and force.

Click here. here to read more about our hydraulic foot pumps.

Enerpac's lightweight hydraulic hand pumps are a practical alternative to heavier steel pumps without compromising performance or safety. Each model is rated up to 10 psi (000 bar). The durable fiberglass-reinforced nylon reservoir and nylon-encased aluminum pump base offer an unbeatable combination of strength, weight and corrosion resistance.

Click here. HERE to read more about the P series (PDF).

The following models: P141, P391, P142, P202, P392, P802, P842.

Weighing as little as 12 kg (26 lbs), the new XC2 cordless battery pump can be taken almost anywhere. This groundbreaking pump combines the power of a traditional electric 0,37 kW (1/2 horsepower) pump with the freedom to lift, pull, split, twist or cut – even in the most demanding applications. Supplied with an optional shoulder strap and an environmentally protected IP67 control pendant, the XC2 makes it easy to get to the job site – and get the job done quickly.

Click here. HERE to read more about the XC2 series (PDF).

The new SC series wireless battery pump is compact, light and precision safe. It gives hydraulic tool users the power to do much more in tight spaces – without extension cords, air hoses and manual pumps. As the first pump with the new Enerpac 54 volt battery platform, the SC Series pump ushers in a new era of exceptional uptime, productive speeds and precision control – all packaged in a compact and portable design.

Click here. HERE to read more about the SC series (PDF).

Specialized's ZC3 series cordless pump offers the portability of a cordless tool without the added weight of an integrated motor, combining freedom of movement with ease of use. Recommended for use with EDCH130 cutters.

The new E-Pulse series in hydraulic pumps represents the best combination of innovative functions and technologies.

The new "Smart Controls" enable the motor to maintain constant power and provide higher flow than traditional pumps and with adjustable speed control provides extra precision when needed.

Click here. HERE to read more about the E-Pulse series (PDF).

In this explanation, we will dive deeper into how hydraulic pumps work, with a particular focus on their different drive systems. We will explore three main types of hydraulic pumps:

Regardless of the drive system used, the main function of the hydraulic pump is to convert energy from either air, battery or electricity into hydraulic energy. It generates the necessary pressure to drive hydraulic cylinders, motors and other hydraulic system components, enabling a wide variety of mechanical tasks

Areas of use: Hydraulic pumps are essential in a variety of industries and applications, and their efficiency and functionality can vary depending on their drive system.

Air driven hydraulic pumps are particularly beneficial in industries that require safety in explosive or hazardous environments. A classic example is the oil and gas industry, where air-driven pumps are used to control valves and pump hydraulic oil. In the railway sector, they are indispensable for lifting and positioning heavy rail cars and locomotives. Their portable nature makes them ideal for field work and in situations where a constant air supply is available.

On the other hand, battery-operated hydraulic pumps are extremely useful in the emergency services. In car accidents, these pumps are used to quickly lift or cut apart vehicle bodies and rescue people. Their portability and ease of use make them ideal in emergency situations. In the agricultural sector, battery operated hydraulic pumps are used to lift and maintain heavy farm equipment in the field. Also in the offshore industry, especially on offshore platforms, they are valuable for carrying out maintenance work and repairs where there is not always an available power source.

Electric hydraulic pumps are the most common and are used in a wide range of industries. In the manufacturing sector, they are indispensable for controlling machines and moving parts in the production process. In the construction industry, they operate cranes, elevators and other heavy machinery that require reliable and continuous power. In the aerospace industry, they are used to control aircraft landing gear and perform maintenance and repairs.

By choosing the right type and drive system for hydraulic pumps based on the specific needs of each industry or application, efficiency and reliability can be achieved in hydraulic systems. It is clear that these pumps play a central role in enabling a variety of mechanical tasks in various industries.

Regardless of which of these hydraulic pumps you need, we at Bengstssons Maskin can help you. Optimize your business with our reliable pumps. Make the smart choice - Buy your pumps at Bengtssons Maskin today and benefit from reliable quality and expertise!

Are you looking for lifters? We have plenty of telephone frames in standard design and we often make adaptations. Read more about our products...

The FLEXOMAX series consists of three different coupling variants: GSN, G and GBN.

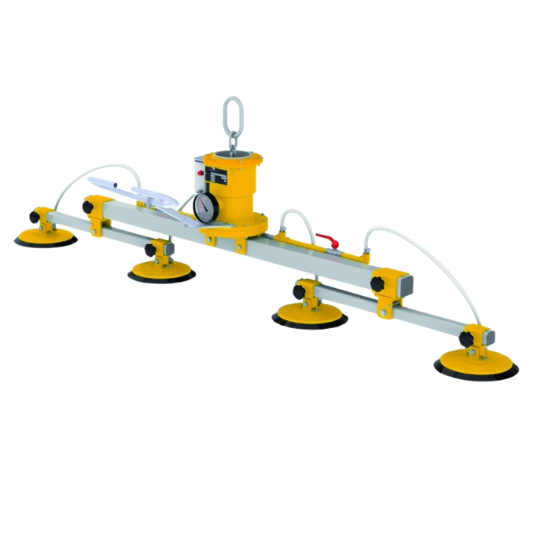

Vacuum lifters for sheet metal, stone or other smooth "plates". We have both self-generating vacuum lifts, which do not need an external power source, and lifts.