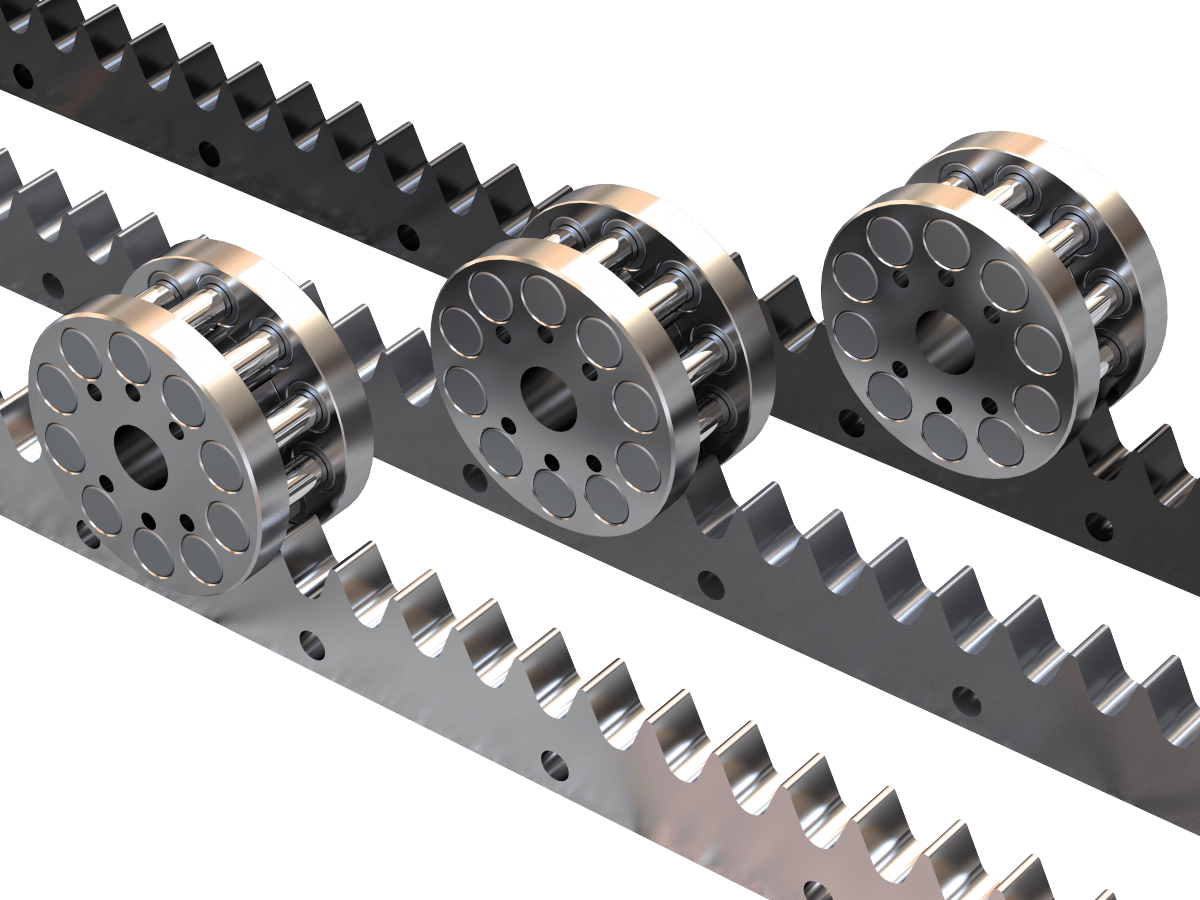

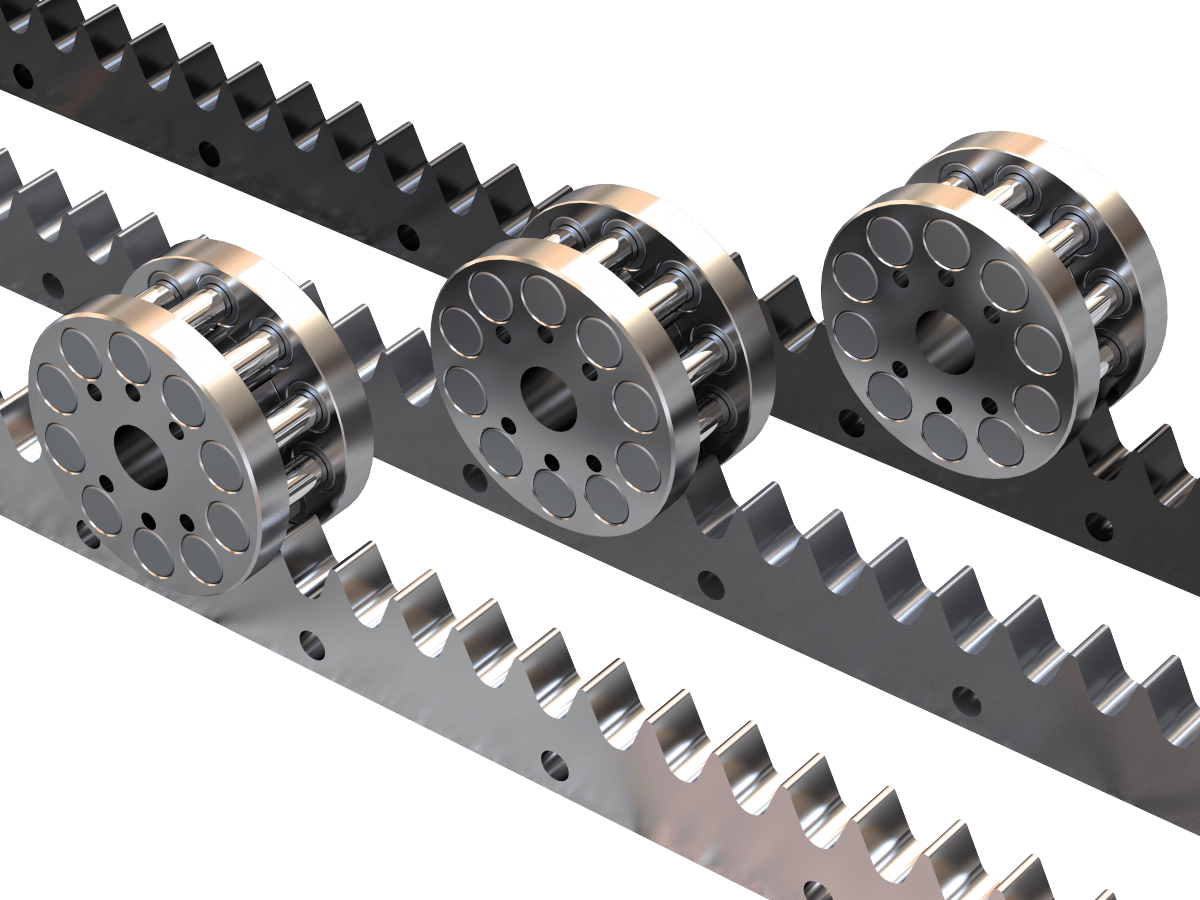

Nexen RPS system

Nexen RPS system for linear and rotary precision movements. Read more about our products here.

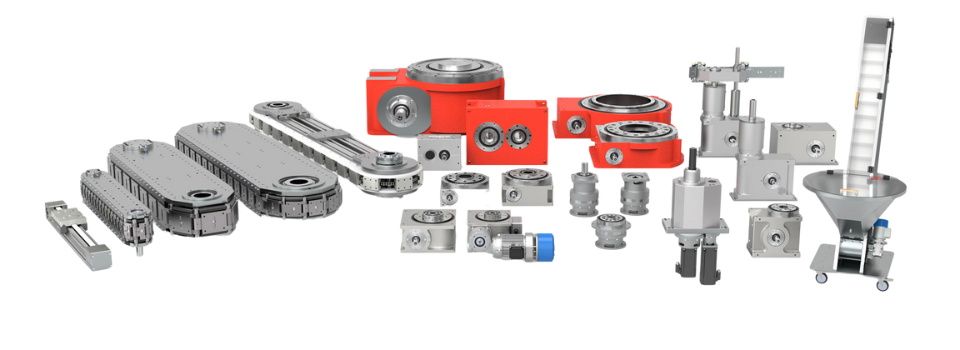

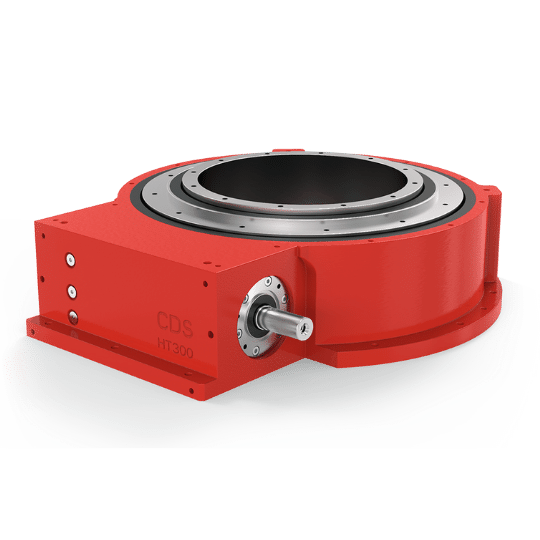

Indexing gears and indexing tables are simple, proven and reliable machine elements. Bettinelli is a world-leading manufacturer from Italy.

Packaging machines, assembly machines, step conveyors and welding machines are some examples of applications where we have great expertise.

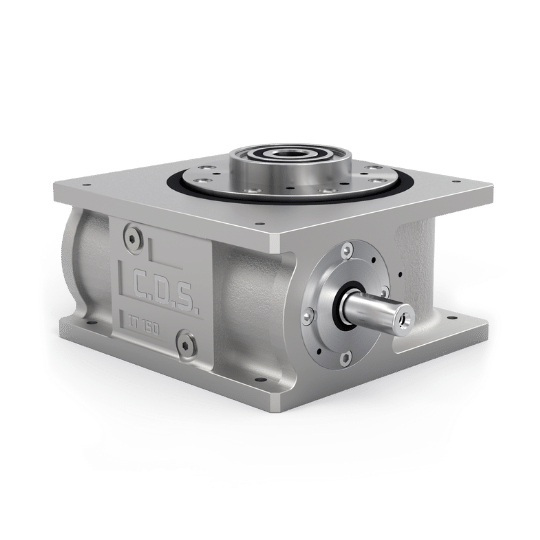

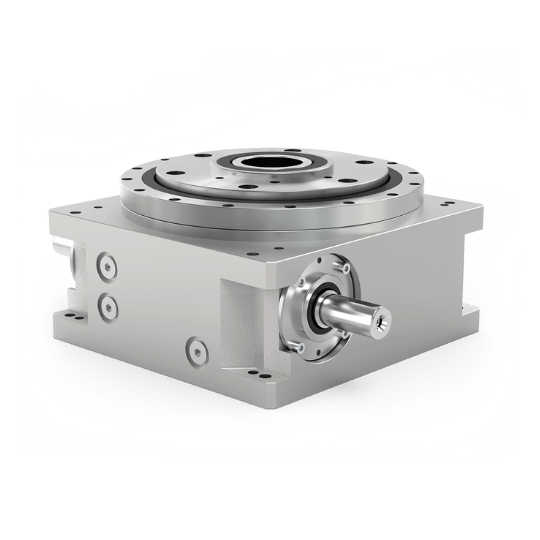

An indexing table converts – in simple terms – a constant rotary motion into a step-by-step motion. This is done with the help of an indexing mechanism built into a gear housing.

Indexing tables are equipped with a strong internal storage that can carry large loads in different directions.

Our indexing gears and indexing tables are available in several different designs for different purposes.

• Number of sizes: 7

• Number of stops/360 degrees : 1-36 by default (also uneven divisions)

• Output flange disc with four-point ball bearing for high loads

• Stationary center hole for serviceequipment e.g. electricity, air, hydraulics

• Maximum accuracy between stations

• Through input shaft

• Hardened cam curves

• Directly mounted worm gear operation possible

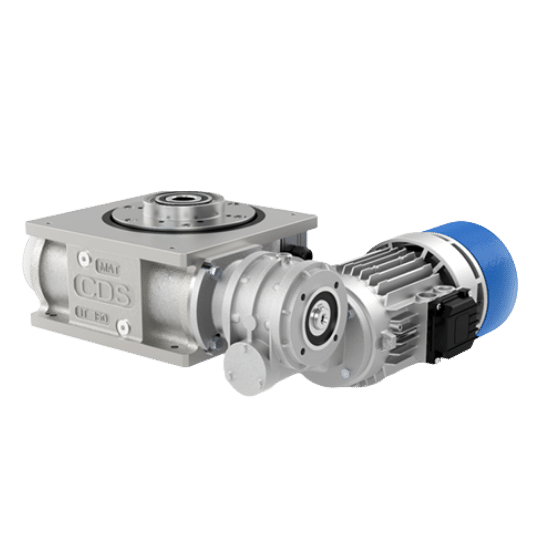

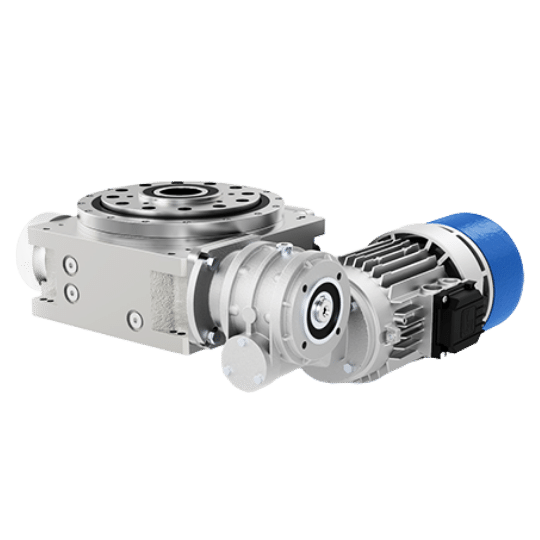

ITP is the packaged version of IT.

It is equipped with a gearbox and three-phase induction motor.

sizes: ITP75 – ITP100 – ITP150 – ITP200 – ITP300

Number of stops: from 2 to 12

Index Angle: from 300° to 330°

Dynamic capacity: from 10 to 5500+ Nm

Output motion shaft bearing

- Max axial force: from 1000 to 45000 N

– Tilt: from 10 to 650 Nm Central hole: from 9,8 to 59,8 mm

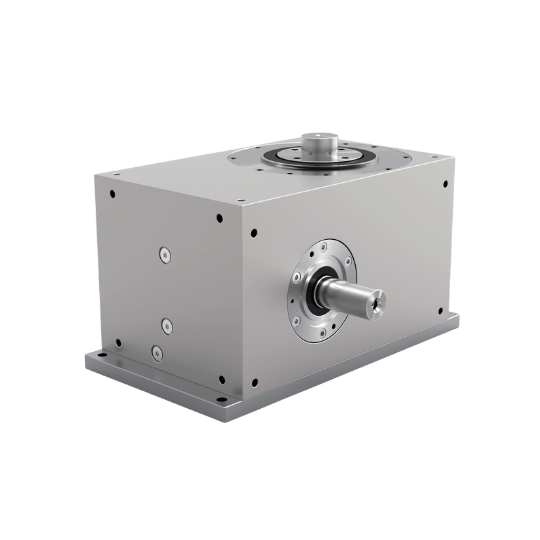

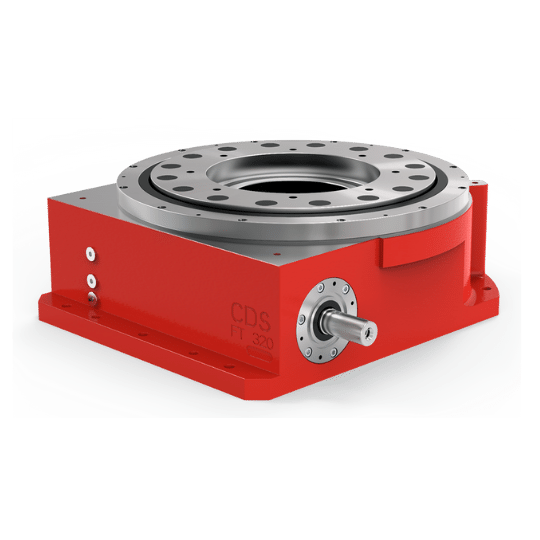

An indexing table converts – in simple terms – a constant rotary motion into a step-by-step motion. This is done with the help of an indexing mechanism built into a gear housing.

Indexing tables are equipped with a strong internal storage that can carry large loads in different directions.

Our indexing gears and indexing tables are available in several different designs for different purposes.

• Number of sizes: 11

• Number of stops/360 degrees: 2 – 36 (also uneven divisions)

• Output flange disc with four-point ball bearing for high loads

• Stationary center hole for serviceequipment e.g. electricity, air, hydraulics

• Maximum accuracy between stations

• Through input shaft

• Hardened cam curves

• Directly mounted worm gear operation possible

• Through input shaft

• Hardened cam curves

• Directly mounted worm gear operation possible

ITP is the packaged version of IT.

It is equipped with a gearbox and three-phase induction motor.

sizes: TRP80 – TRP110 – TRP160 – TRP210 – TRP315 – TRP400 – TRP470

Number of stops: from 2 to 12

Index Angle: from 300° to 330°

Dynamic capacity: from 60 to 10+ Nm

Output motion shaft bearing

– Max axial force: from 18 to 000 N

– Tilting: from 500 to 6800 Nm

– Central hole: from 12 to 130 mm

Standard discs for the TRP series are now available to add - either fixed or rotated disc. Contact us for more information!

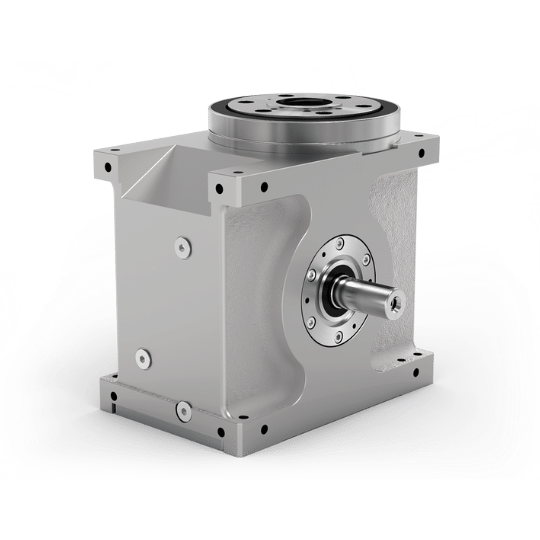

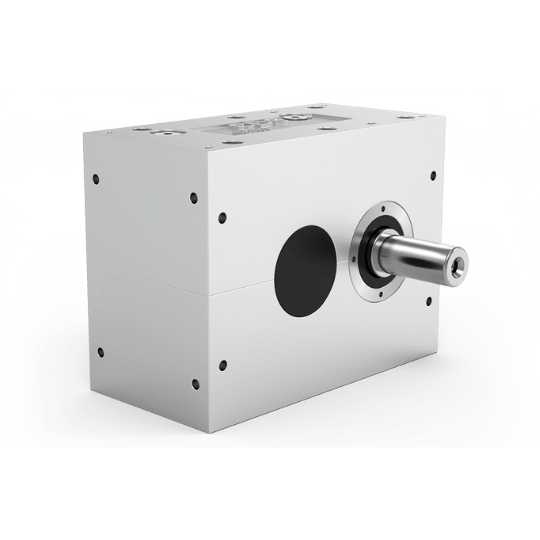

A globoid gear converts – in simple terms – a constant rotating movement into a stepwise movement. This is done with the help of an indexing mechanism built into a gear housing.

Globoid gears have all input and output shafts offset by 90 degrees and have very high repeat accuracy.

Our globoid gearboxes are available in several different designs for different purposes.

• Number of sizes: 9

• Number of stops/360 degrees: 1 – 24 as standard (also uneven splits) in special version wafers 1 – 36

• Symmetrical cast iron housing (size 63 in aluminium)

• With outgoing shaft pin or flange connection

• Hollow shaft as an alternative version against order

• Very high repeat accuracy

• Hardened comb profiles

• Directly mounted worm gear operation possible

A globoid gear converts – in simple terms – a constant rotating movement into a stepwise movement. This is done with the help of an indexing mechanism built into a gear housing.

Globoid gears have all input and output shafts offset by 90 degrees and have very high repeat accuracy.

Our globoid gearboxes are available in several different designs for different purposes.

• Number of sizes: 2

• Number of stops/360 degrees: 8 – 12 (also uneven divisions)

• Outgoing flange connection with angular contact bearing

• Maximum dividing accuracy

• Through input shaft

• Hardened can curves

• Very complicated movements are possible in this series

• Directly mounted worm gear operation possible

An indexing gear converts – in simple terms – a constant rotary movement into a stepwise movement. This is done with the help of an indexing mechanism built into a gear housing.

Our indexing gears are available in several different designs for different purposes.

• Number of sizes: 8

• Number of stops/360 degrees: 1 – 2 – 3 – 4 – 5 – 6 – 7 – 8, in special versions also 0,6 – 0,75 – 1 – 1,33 – 1,5 – 2 – 5 – 10

• High repeat accuracy

• Symmetrical aluminum housing

• Hardened comb profiles

• Directly mounted worm gear operation possible

FTP is the packaged version of FT.

It is equipped with a gearbox and three-phase induction motor.

Sizes: FTP320 – FTP450 –

FTP590 – FTP850 Number of stops: from 6 to 36+

Dynamic capacity: from 1600 to 300000+ Nm

Output motion shaft bearing

- Max axial force: from 45 to 000 N

- Tilt: from 8500 to 44000 Nm Central hole: from 160 to 1000 mm

Choosing the right indexing gear is not a complicated calculation, but rather extensive and time-consuming.

We therefore use a Windows-based calculation program that considerably simplifies the calculation work. The program gives us the opportunity to vary a large number of parameters such as movement pattern, moment of inertia, load spread, indexing speed, etc.

The result of the calculations is presented in a printout that indicates, not only the suitable solution for indexing gear, but also information about suitable drive equipment - gear/motor etc. With the help of the program, we also get references to what can/should be changed to find an optimal solution as well technical as well as commercial.

For our customers, this service is free of charge and you can get more information from our sales staff.

Nexen RPS system for linear and rotary precision movements. Read more about our products here.

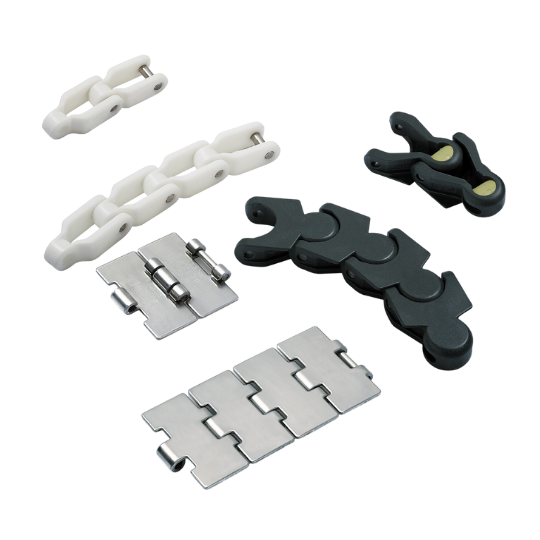

Regina Catena plastic & steel chains and modular belts are a very comprehensive product range. Read more about the products here.

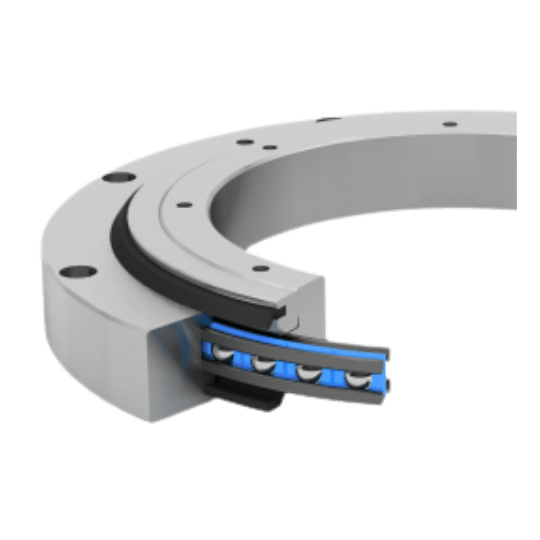

Slewing bearing is a wire bearing that is fitted with an inner and outer ring. The advantage of this system is i.a. that the outer and inner ring can be made of materials other than steel – eg aluminum for light weight.