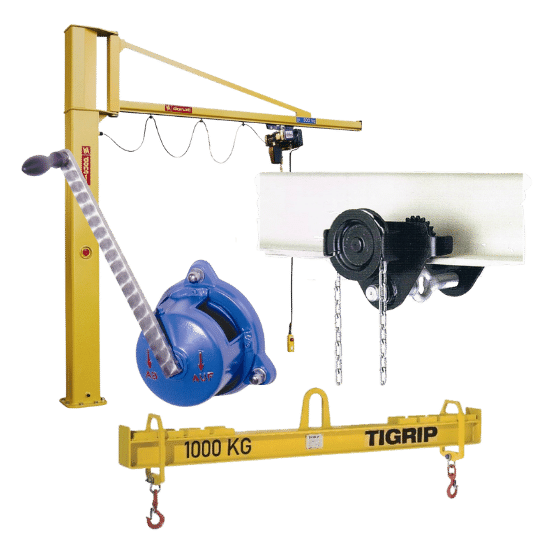

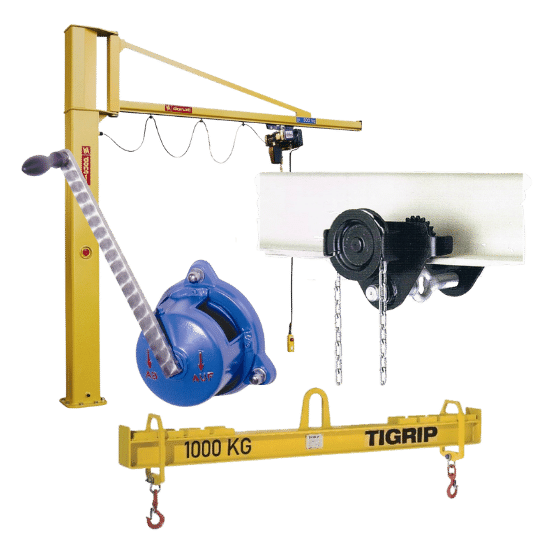

Other lifting

Here we have gathered other products within lifting. You will find various hand winches, slewing cranes, beam trailers and lifting devices.

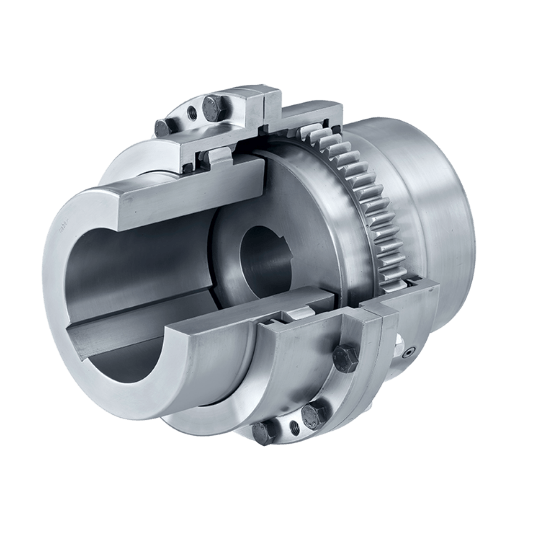

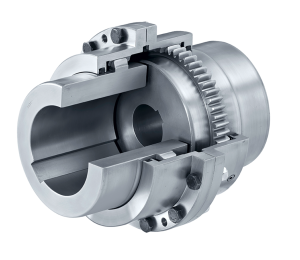

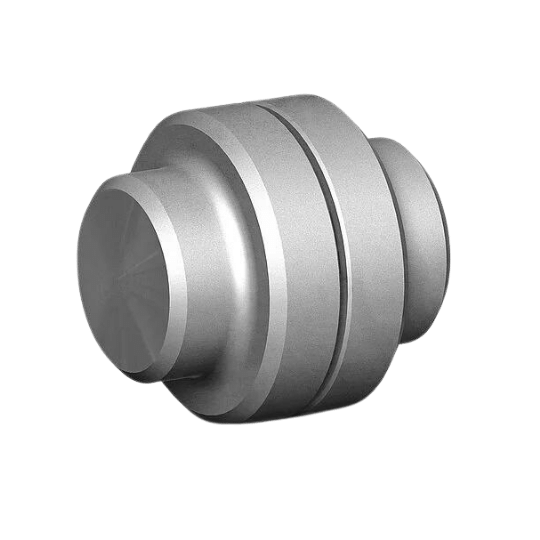

Products > Heavy Duty > Gear couplings

Renk is one of the world's leading manufacturers of spur gear couplings. Only a limited range of standard couplings is presented on our website.

For further information on, for example, high speed couplings for speeds up to 40 rpm, please contact our sales representatives.

For decades, the RENK toothed coupling has been a reliable product all over the world. With this spindle coupling based on the arc tooth technology, RENK has taken this technology a step further and developed a shaft coupling that is mechanically rigid yet movable in all directions.

The shape of the teeth enables purely mechanical mobility without any elastic elements. This product is primarily developed for applications where large torques must be transmitted as compactly as possible.

The spindle coupling can accommodate large deviations and is perfectly suited to most applications in steel mills, whether cold or hot rolling mills.

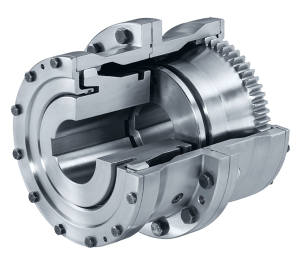

The primary task of overload protection in machinery systems is to protect valuable machinery from damage due to the occurrence of unexpected and increased torques.

However, it is impossible to completely rule out machine breakdowns caused by sudden overloads that cannot be predicted.

However, a single incident of damage can be far more expensive than an effective overload protection type HYGUARD®.

Appropriate safety equipment is therefore still necessary to protect such systems.

With HYGUARD® hydraulic safety couplings, the torque is transmitted exclusively via friction between the hydrostatically loaded surfaces of the shaft and hub. It works without slipping as long as the preset torque is not exceeded. If the torque exceeds this value, the hydrostatic pressure is quickly released, shutting down the drivetrain immediately.

Commissioning requires some time. The system only needs to be placed under pressure once more.

Here we have gathered other products within lifting. You will find various hand winches, slewing cranes, beam trailers and lifting devices.

The FLEXOMAX series consists of three different coupling variants: GSN, G and GBN.

Best flanging tools on the market! We can now proudly present the entire range from Equalizer. On this page you will find all products in this area.