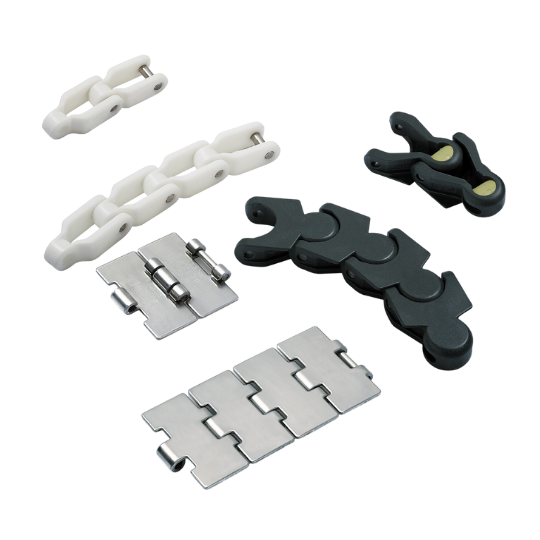

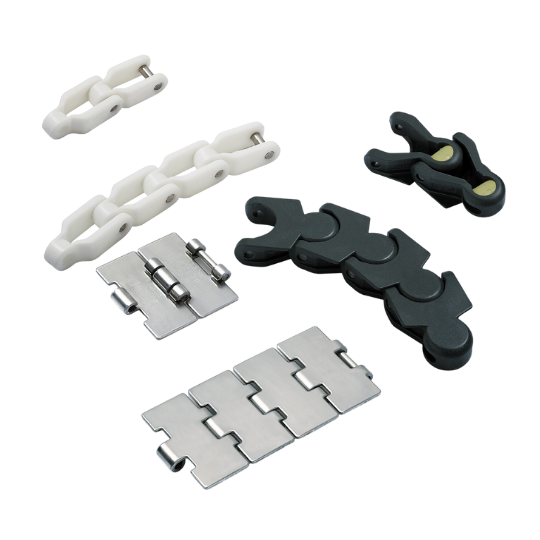

Conveyor chains – modular belts

Regina Catena plastic & steel chains and modular belts are a very comprehensive product range. Read more about the products here.

Regina Catena plastic & steel chains and modular belts are a very extensive product range and impossible to present in detail on the website. A product catalog is available in pdf format under each product group.

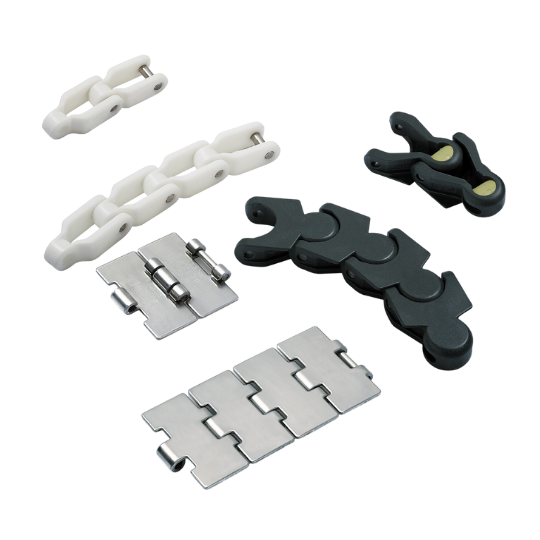

Regina Flite Top band chains in steel are available in a very large selection in both steel and stainless steel.

We present only parts of the product range on these pages and refer to the pdf catalog for further information.

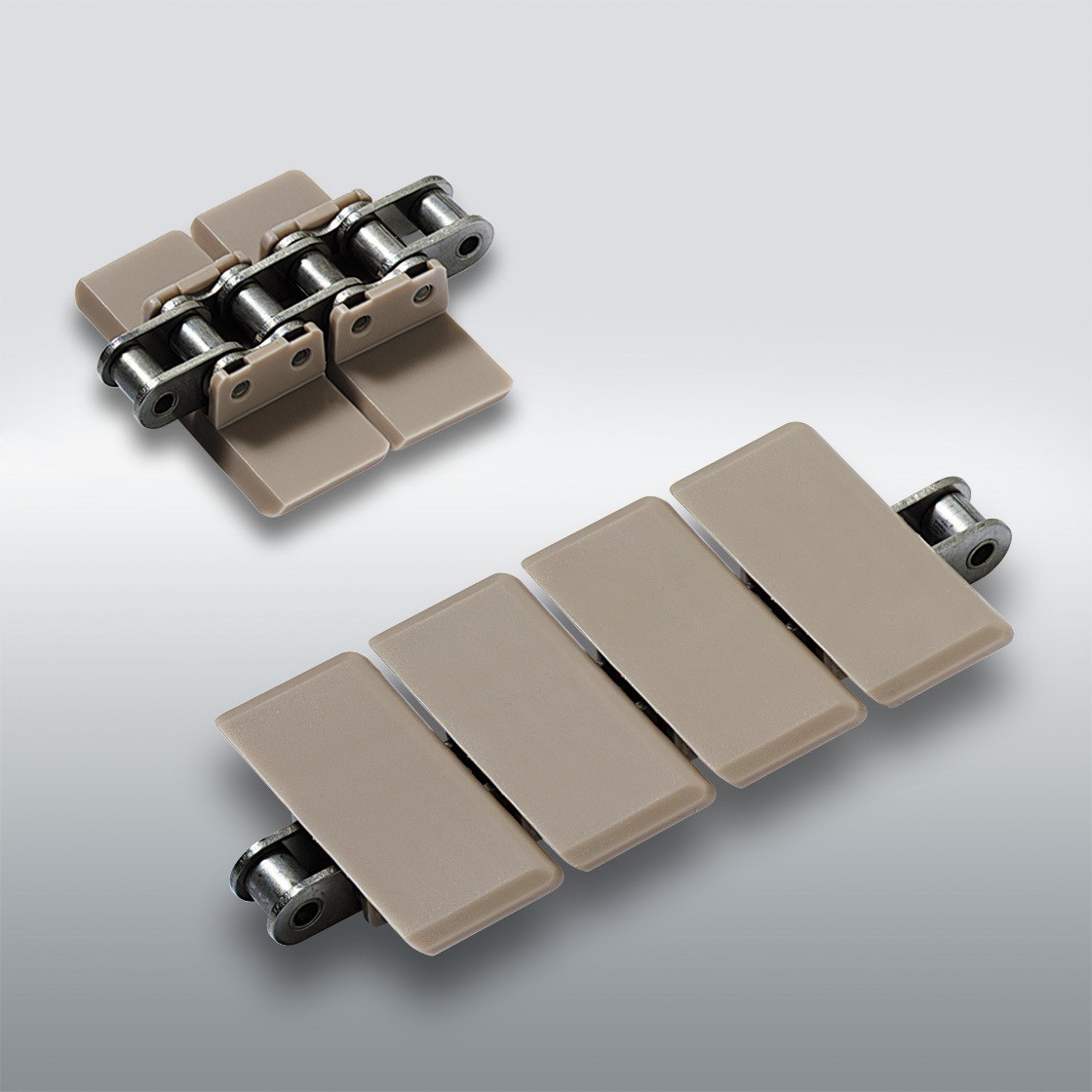

In steel with an underlying roller chain for transport purposes. These chains are constructed with a supporting roller chain made of steel or stainless steel.

The plates are of the "snap on" type and can be obtained in steel or stainless steel. Widths between 82,6 mm and 190,5 mm.

These chains are available in case hardened steel and stainless steel in a wide range of widths from 82,6mm to 190,5mm

The stainless versions are available with a reduced gap between the plates for better product stability.

These chains are available in case hardened steel and stainless steel in a wide range of widths from 82,5mm to 190,5mm

To keep the chains in place in the curve segments, there are three different possibilities:

With underlying roller chain for transport purposes. These chains are equipped with a supporting roller chain made of steel or stainless steel. The plates are available in steel or stainless steel. The design provides a chain that can handle high loads and/or long transport systems with a few drive stations.

Widths from 82,6 mm to 190,5 mm

For transport applications where higher friction is needed, these stainless steel chains are a good option.

In the flee cases, these chains can work with an incline of up to 25 degrees.

The friction coating is made of Nitrile rubber and vulcanized against the chain for best adhesion.

Widths from 82,6 mm to 190,5 mm

These chains are available in a large number of variants in both straight-running and side-bending variants.

Most of the chains are also available in different plastic materials – all with unique properties that make it easy to find the right chain for the application.

These chains are available in the same variants as other straight belt chains without friction coatings.

However, the material is limited to LW Acetal.

These side bending chains are equipped with friction plates to provide better friction between the chain and transported goods.

Usable in conveyors with incline or other applications where better friction is necessary.

Widths from 82,6 mm to 114,3 mm

The material is Acetal LW

These chains are available in widths from 82,5mm to 190,5mm

The material variants are:

LW Acetal which combines high breaking load with low friction

UP Acetal which combines improved wear resistance with low friction

DK Acetal reinforced with Kevlar for truly demanding applications

These chains are equipped with a supporting roller chain made of steel or stainless steel. The plates are of the "snap on" type and easily replaceable.

The carrying chain makes it possible to crane heavy loads over long distances with a minimum of drive stations in the conveyor.

Widths from 34,9 mm to 50,8 mm

Also variants for any transport direction

The material in the plates is acetal LW

These chains are equipped with supporting roller chain made of steel or stainless steel. This makes it possible to build conveyors for large loads in long conveyors with a minimum of drive stations.

Certain variants are available with overlapping plates for minimum play.

Widths from 31,8 mm to 406,4 mm

The material is acetal LW

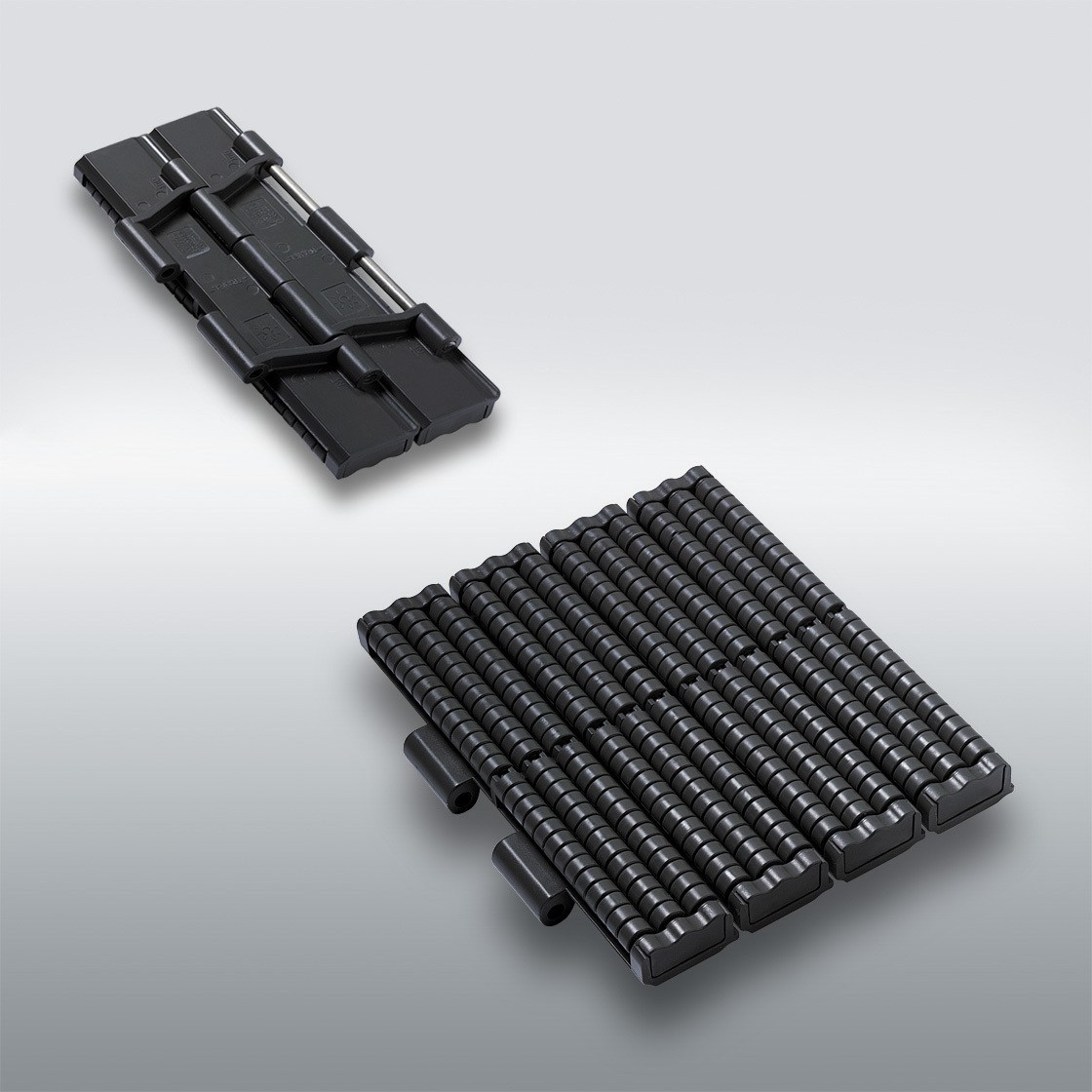

These belt chains are intended for conveyors with accumulation of goods.

The top plate consists of a large number of rollers that reduce the pressure

The rollers have a maximum difference between Di and Dy for minimum rolling friction and lowest noise level

The material in the chain is Acetal

Widths from 190,5 mm to 304,5 mm

These side bending plastic chains are intended for conveyors with accumulation.

The top plate is equipped with a large number of rollers for a minimum of friction. This reduces the pressure from underlying goods and minimizes the risk of pressure damage.

Widths from 190,5 mm to 304,8 mm

The material is acetal

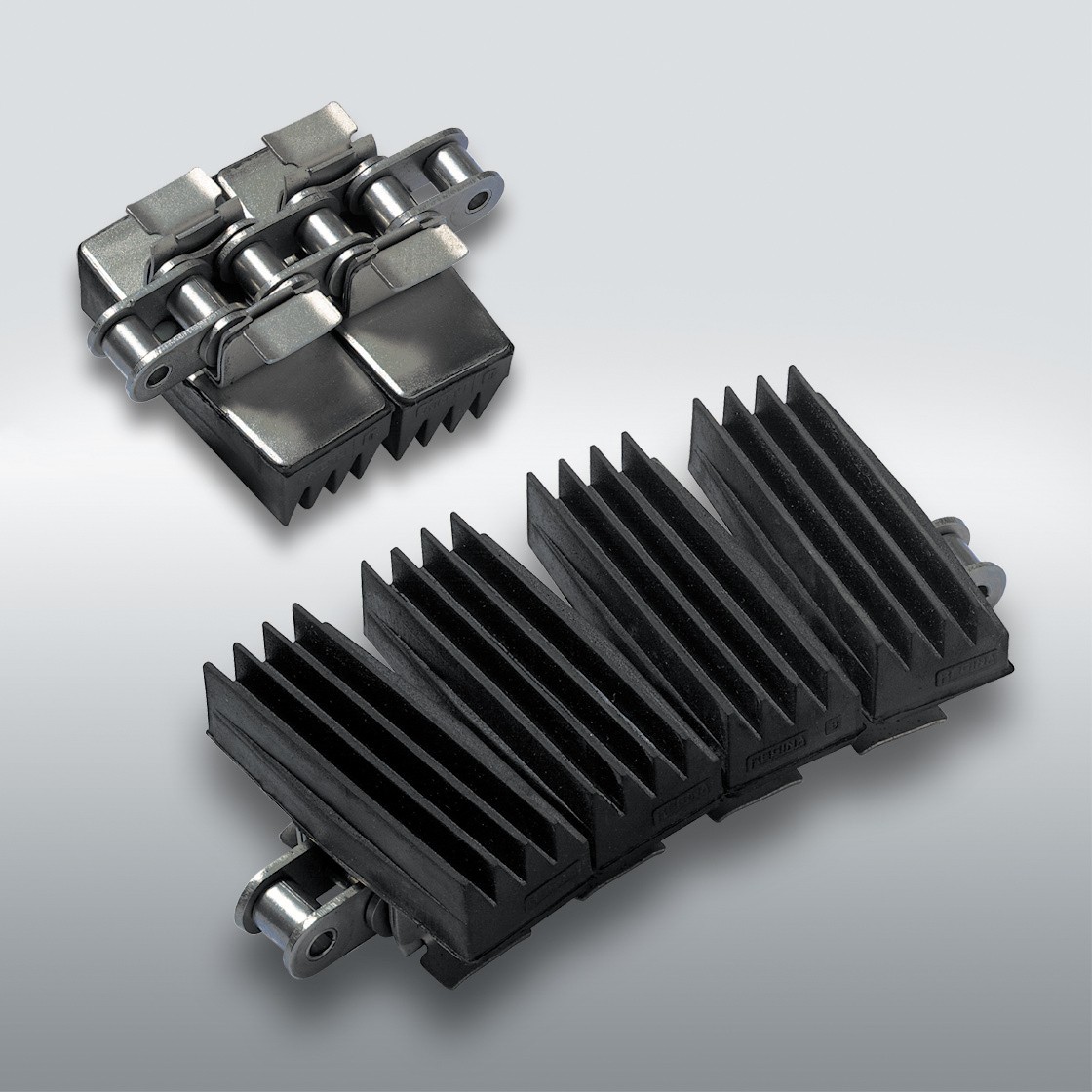

This series of chains is designed for elevator transport of e.g. cans but can of course also be used for other types of applications.

The basic chain is made of steel or stainless steel and equipped with a "snap on" type rubber catch.

The carrier is available in a number of designs that provide different hard pressure against the transported product.

Available in widths from 82,6 mm to 114,3 mm

These chains are a cost-effective way to transport smaller packages.

They are available in a large number of designs and materials. They are common in the dairy industry, among others.

The most common cardan chain in the dairy industry.

The material is acetal and the color is white.

A large assortment of sprockets is available.

This series is basically the same as series 1702 but has been fitted with an angled guide rail to keep the chain in place when cornering. It is therefore not necessary to use turntables.

The material is white acetal or light brown acetal LW.

A large selection of sprockets is available.

This series was originally developed for the transport of return trays in the brewing industry.

It can of course be used for other types of transport goods where a simple cost-effective transport solution is desired.

Simplest variant in this series. The material is white acetal with stainless steel bolts. For further information, we refer to the pdf catalogues.

Basically the same design as series P 600-O but equipped with angled guide plates to keep the chain in place in the curves.

Basically the same construction as series P 600-O but equipped with a top plate. This makes this series better suited for transporting unstable goods. The material is white acetal.

Basically the same chain as the P 2600-C but fitted with angled guide plates to keep the chain in place when cornering.

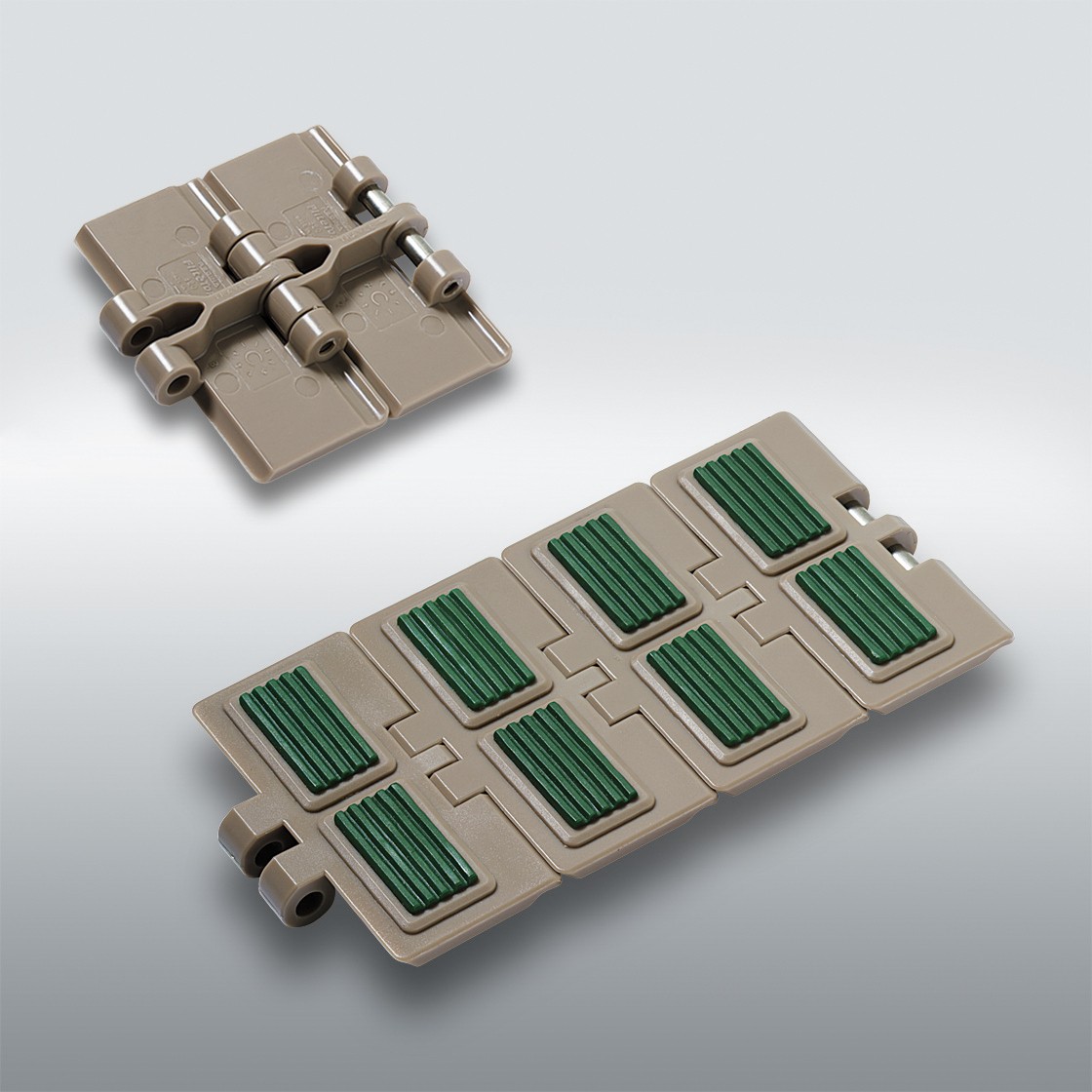

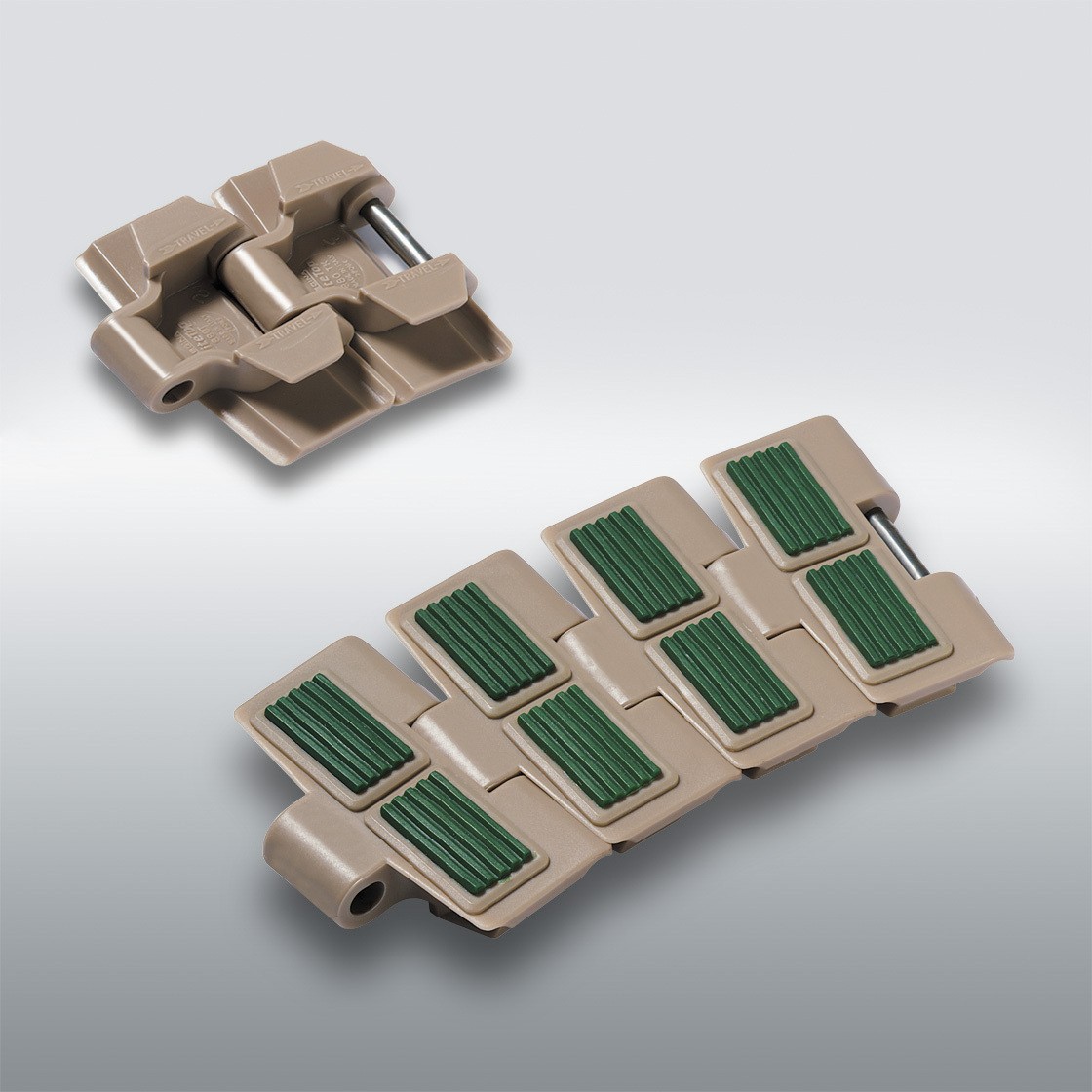

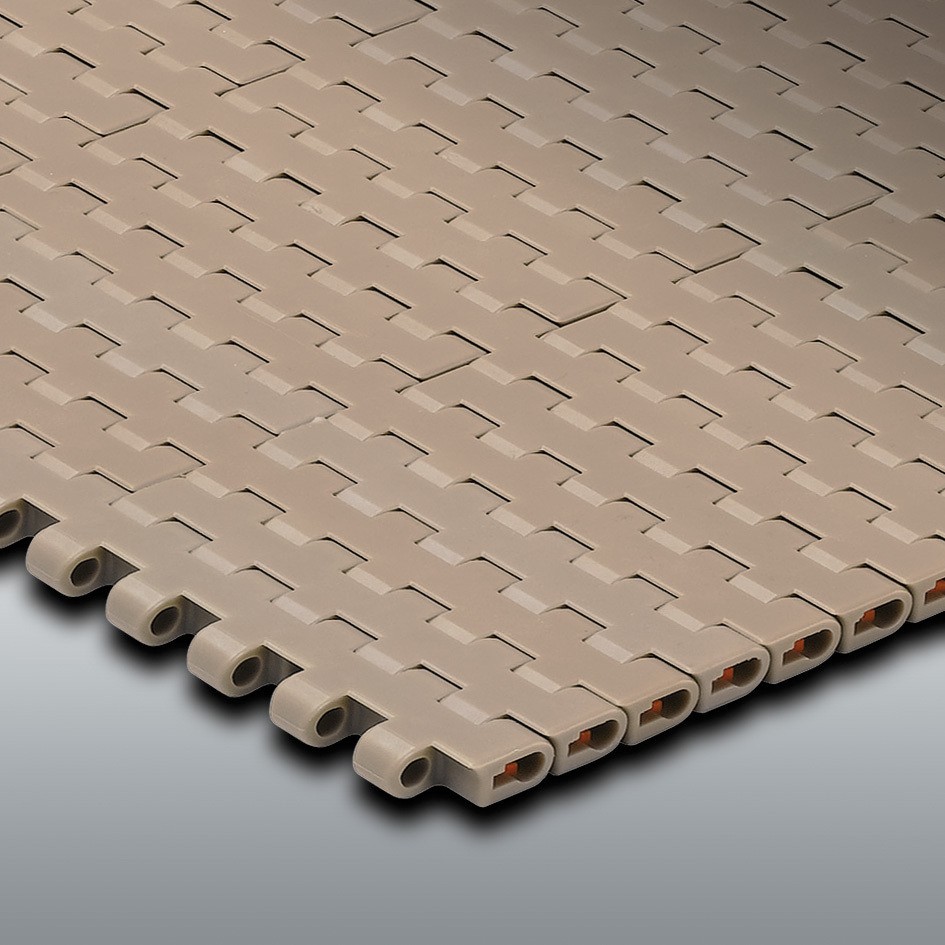

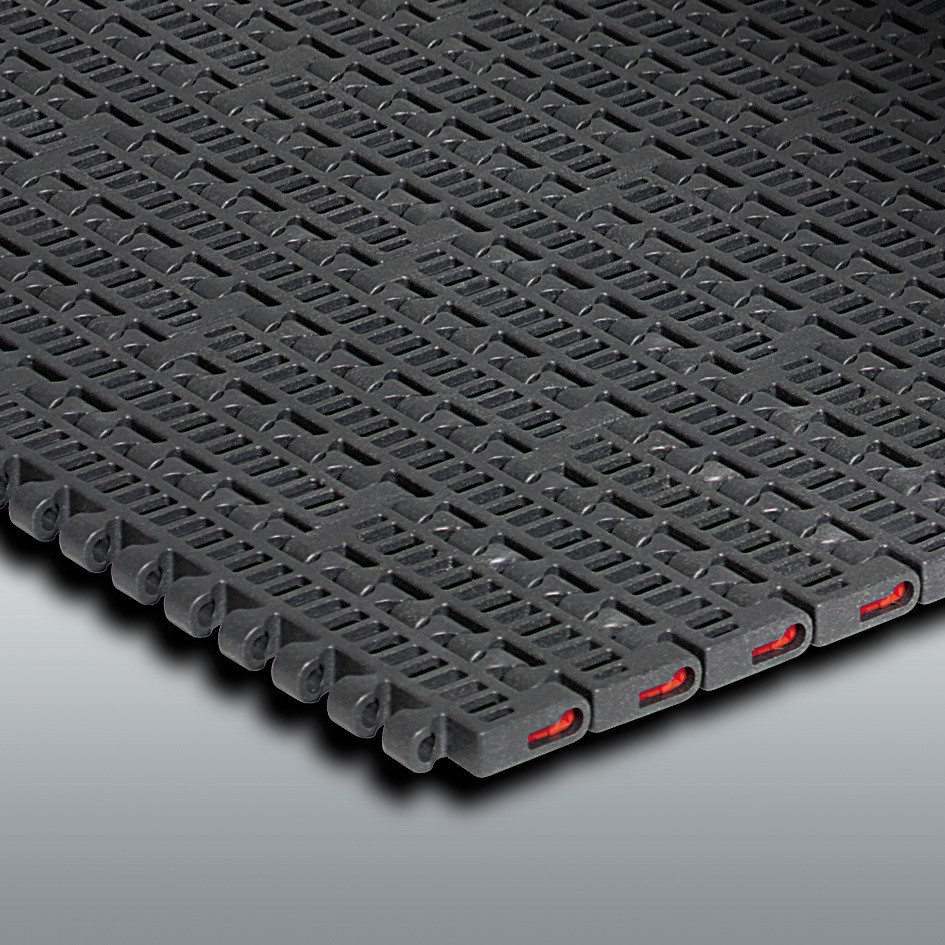

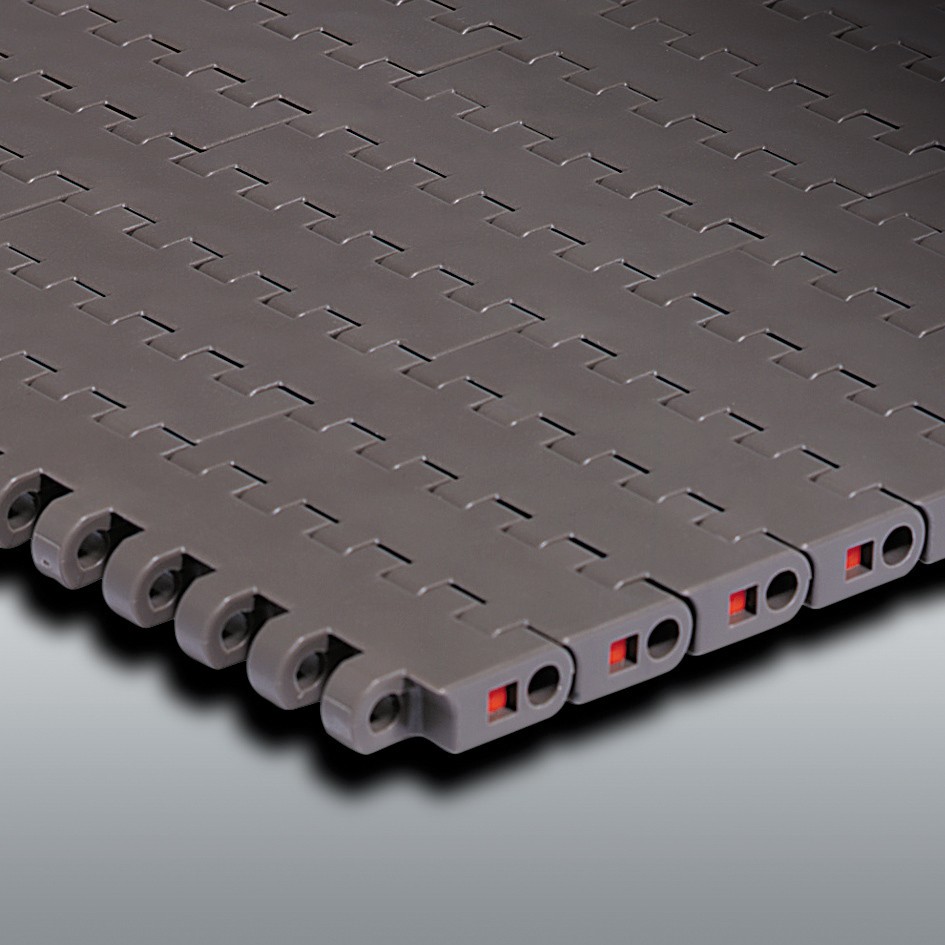

Regina Matveyor modular belts are a very wide range of modular plastic belts for transport purposes.

The range is extensive and is only presented in summary on the website. For complete information, we refer to the pdf catalogue

This series is the latest addition to the Matveyor family. It is suitable for light transport where it offers many advantages.

With its 12,7 mm, the modular belt's pitch is the smallest on the market and makes it possible to drive over very small wheel diameters.

For the drive there is a very large selection of sprockets with wedge grooves or square holes

Pitch: 12,7 mm

Module width 85 mm and multiples of this, e.g. 170 mm, 255 mm etc.

Material: Light brown acetal LW, dark gray acetal DK with Kevlar and PP dark gray polypropylene

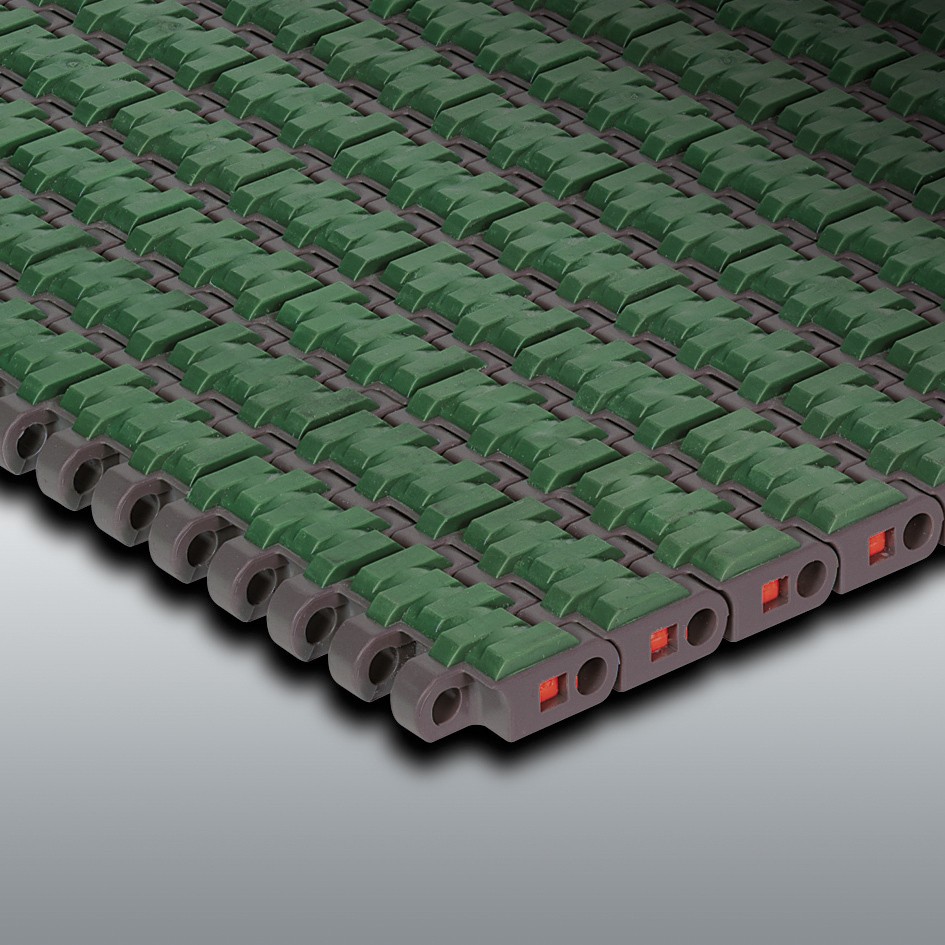

A modular belt for applications where a higher friction is desired.

The module width is 85 mm and multiples of this, i.e. 170, 255, 340 mm, etc.

The material is dark gray acetal.

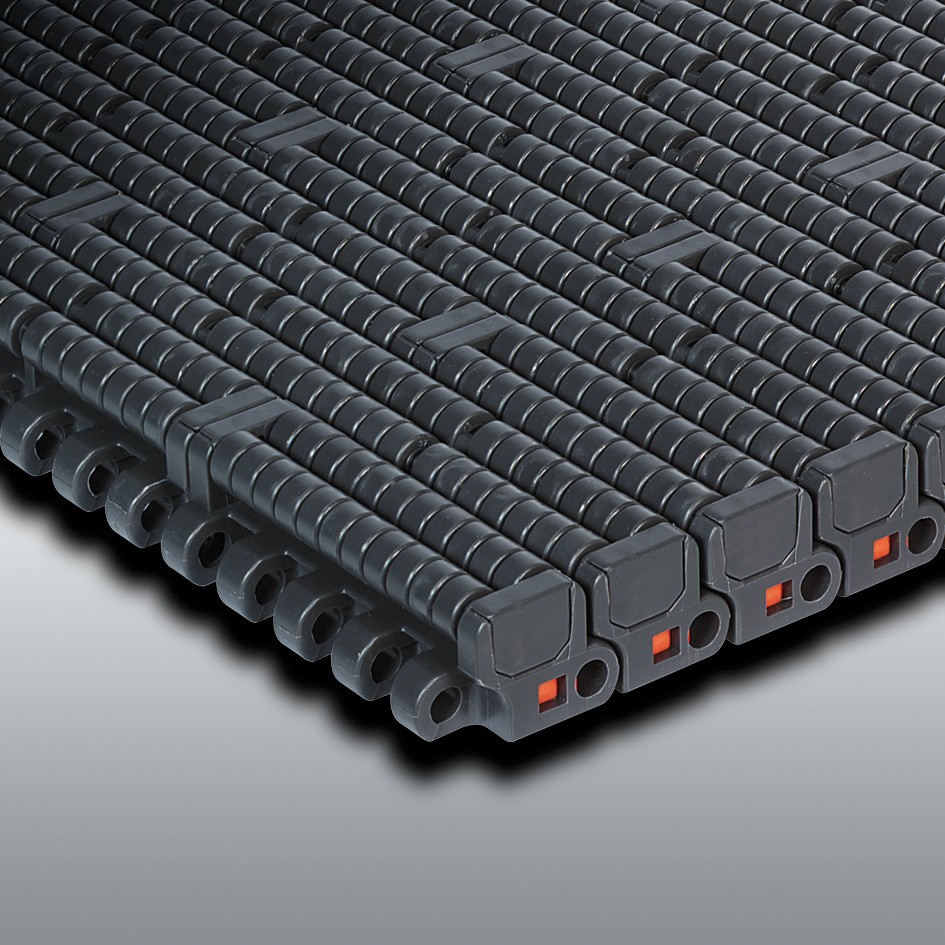

This modular belt is equipped with a large number of rollers on the top plate for accumulating trap sort paths.

The rollers have a large difference between Di and Dy and thus provide extremely low friction. This reduces pressure damage to accumulated goods, so-called "back line pressure".

The module width is 85 mm and multiples of this, i.e. 170, 255, 340 mm, etc.

The material is dark gray acetal.

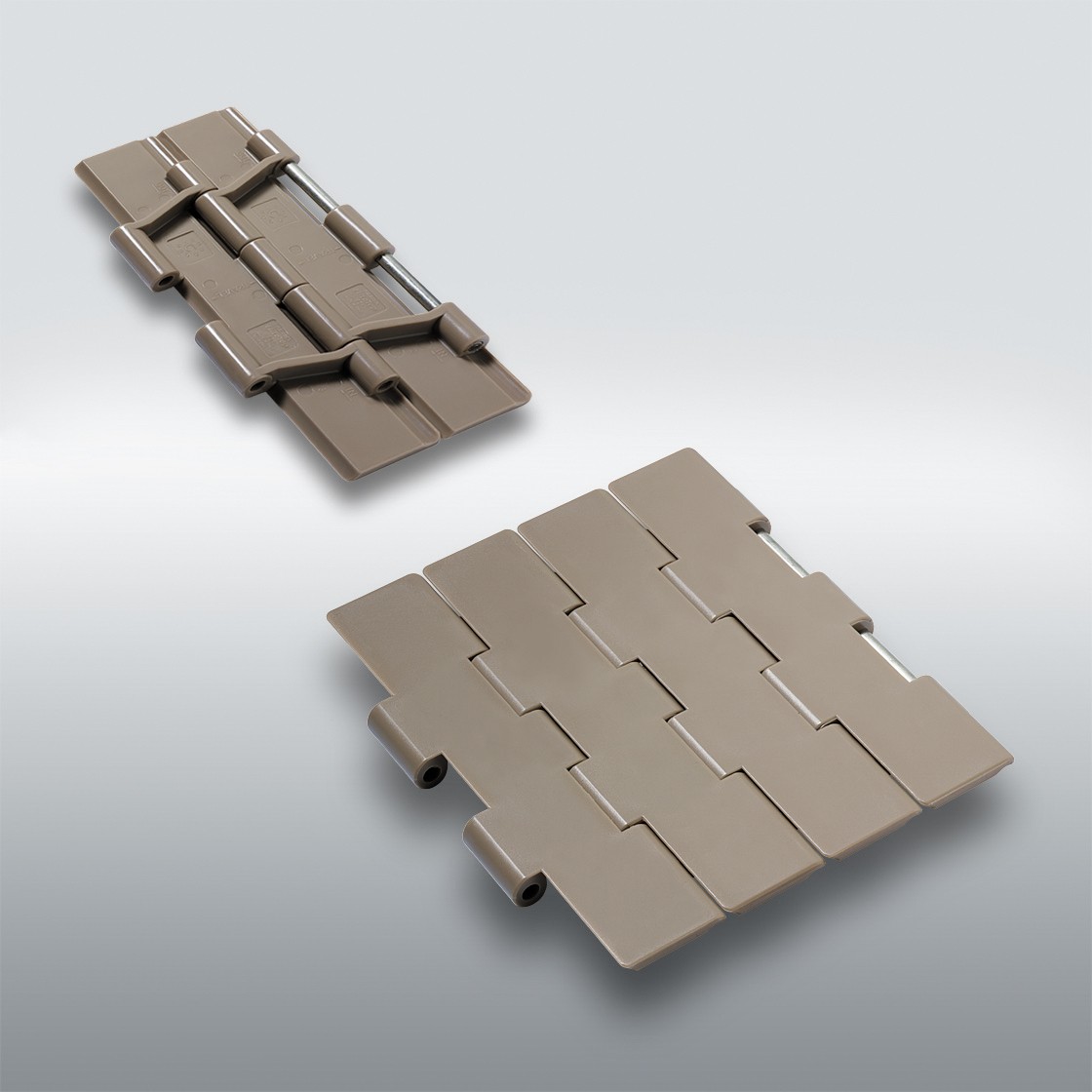

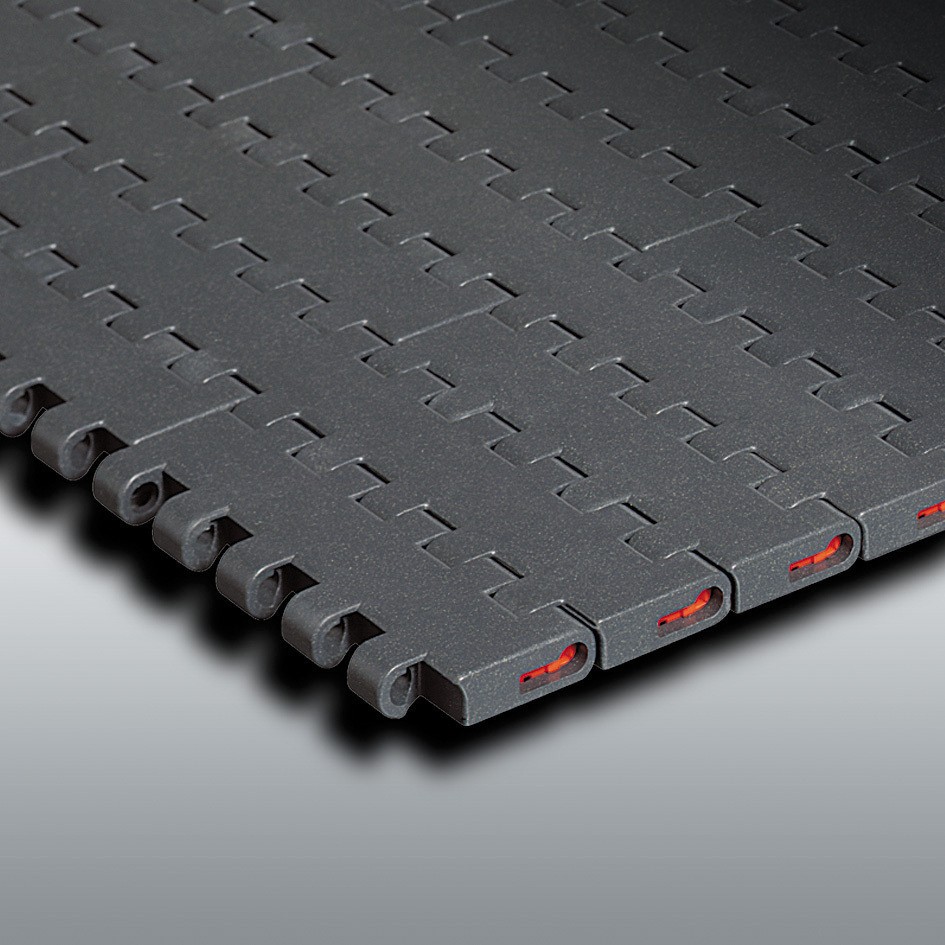

This series is suitable for the transport of heavier goods where a completely smooth transport surface is required.

Available both as defined widths 82,6 mm and 83,8 mm or modular

Pitch 25,4 mm

Materials: Light brown LW acetal, dark gray DK acetal with Kevlar reinforcement and dark gray PP polypropylene.

Module width 85 mm or multiples of this, e.g. 170 mm, 255 mm, etc

This modular belt is perforated to drain liquids or allow air to pass through.

Especially developed for the transport of aluminum cans but can of course be used in other types of applications.

Low friction in combination with stable product transport.

Pitch: 25,4 mm

Module width: 82,6 mm or module built-up with multiples of the module 85 mm, i.e. 170 mm, 255 mm, etc.

Metarial: Light gray LW acetal, Dark gray DK acetal with Kevlar reinforcement or dark gray PP polypropylene.

These side bending conveyor chains are designed to work with Matveyor modular belts series 600, 1600 and 1500.

This makes it possible to build transport systems where one of these chains handles, for example, the input of products to a wider modular belt.

The dimensions of the chains are adapted to those of the modular belts so that a safe transfer can take place towards the modular belt without unstable products falling.

The ULTOP chains are designed for the transport of unstable goods. They can work together with the Flite Top chains in the 793T series.

This chain has a defined width of 83,8 mm

A strong construction with a very smooth top side and strong underside for good wear resistance.

They can be mounted next to each other and also together with Flite Top chain 793. This way you can build conveyors with individual drive and with different speeds.

ULTOP series USPM is a modular system with module width 170 mm or multiples of 85 mm ie 170, 255, 340 mm...etc

A very strong construction with a completely smooth top side and a very strong underside for best wear resistance.

Series USPM can work together with Flite Top chain series 793.

Regina Catena plastic & steel chains and modular belts are a very comprehensive product range. Read more about the products here.

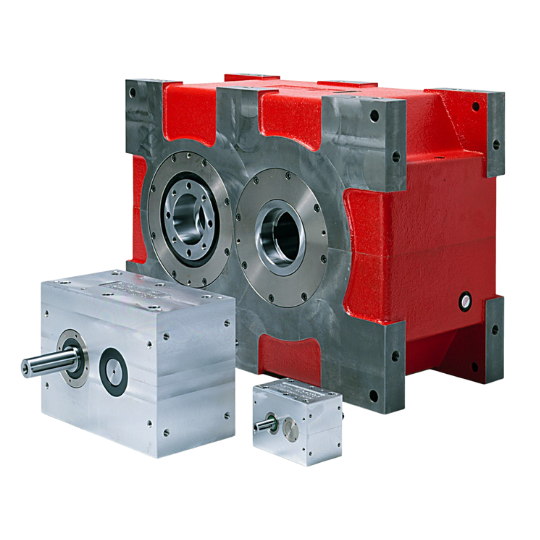

Indexing gears and indexing tables are simple, proven and reliable machine elements. Bettinelli is a world-leading manufacturer from Italy.

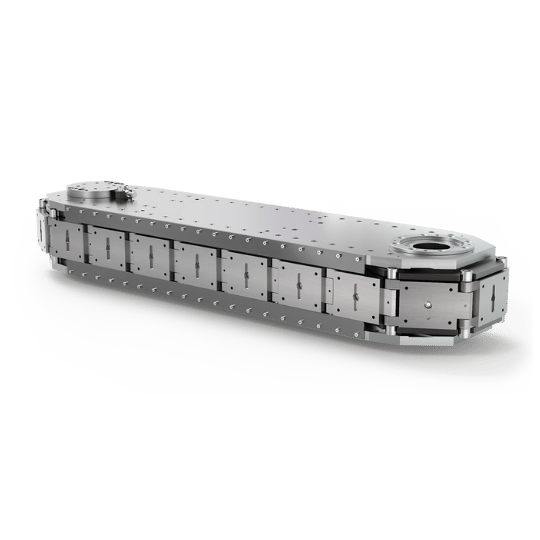

These linear conveyors from CDS enable the industry's highest accuracy and repeatability for automated assembly and manufacturing machines.